Falling number

The Falling Number® System measures the alpha-amylase enzyme activity in grains and flour to detect sprout damage, optimise flour enzyme activity and guarantee soundness of traded grain. Alpha-amylase activity is crucial for final product quality of bread, pasta, noodles and malt. Anyone handling wheat, barley, rye or sorghum intended for these applications will benefit from the Falling Number® system.

The method is standardized by international bodies such as the ICC, AACCI, ISO and ASBC in the standards:

- ICC/No. 107/1 (1968)

- AACCI/No. 56-81.03 (1972)

- ISO/No. ISO/DIS 3093 (1974)

- ASBC Barley 12-A

Applications

Grain trade

In years with rainy weather conditions during harvest, significant sprout damage may occur. In such years every truck load of grain should be tested at the grain intake before unloading and segregated to different silo bins to avoid mixing loads of sound grain with sprout damaged grain. Damaged grain can be used for animal feed or other non-baking purposes such as biofuel. The segregation is important as an uncontrolled mixing of even a few percent of highly sprouted grain with sound grain can make the entire mixture unsuitable for bread making or other end product purposes. Segregation also allows for a careful blending of grains to meet FN specifications particularly at the flour mill.

Because of the quality impact of sprout damaged grain, the FN value is used in price regulations for payment to farmers or traders in national and international trade world wide and for verifying trade contract quality specifications. Typically damaged wheat can receive a 10-30% lower price causing significant economic losses to the farmer or grain trader.

Flour milling and baking

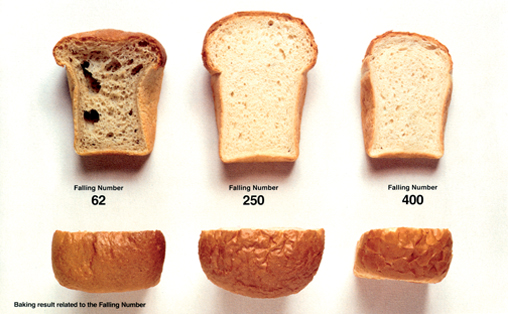

A certain amount of alpha-amylase is necessary for proper baking to occur. The alpha-amylase breaks down starches to provide sugars to help fuel the fermentation process. The amount of enzyme present can have a direct bearing upon the quality of bread produced. When the alpha-amylase activity is right, a high volume bread with firm and soft texture is achieved (FN = 250 in picture). If the activity is too high, a sticky bread crumb and low volume may result (FN = 62 in picture). If the activity is too low, a dry bread crumb with diminished volume may result (FN = 400 in picture). The FN value has an inverse relationship with the alpha-amylase activity meaning the higher the alpha-amylase activity the lower the FN value, and vice-versa.

Millers may use the FN value to produce products with desired or specific FN values. They may blend flours of various FN values to produce a product with a specific amylase activity. Malt can be added to adjust the value in a similar manner.

The exact FN number value desired will be dependent on the type of product to be produced. Breads flours will have different FN values than those of cracker flours. Bakers may use the FN to dictate to their suppliers the type of product they require for their specific endproduct. Bakers also have the option of manipulating their flours in the same manner as the miller. But by requiring the miller to supply a specific product, a baker can receive a consistent product and would not have to adjust this particular aspect of the baking process. Quality control personnel can use the FN value as a quality control tool to help assure the consistency of both incoming and outgoing products. It provides another important tool for savings of time and money.

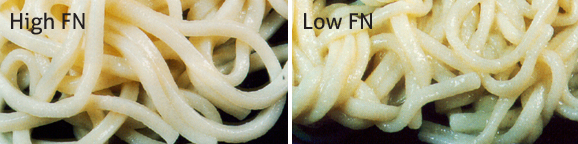

Pasta and noodles

Producing noodles from flour with a low Falling Number® is difficult, with dough handling and cutting problems and product sticking to machinery. It also results in an off-color end consumer product which will be sticky after it is boiled. Using flour with the correct Falling Number® will result in savings through improved processing as well as a higher quality end product.