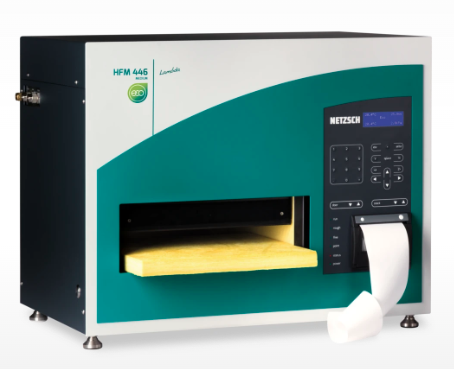

HFM 446 Lambda Medium Eco-Line Heat Flow Meter

Heat Flow Meter HFM 446 Lambda Medium combines innovative features:

Our SmartMode streamlines measurement, evaluation, and reporting processes, empowering operators with intuitive tools such as AutoCalibration, wizards, user-defined methods, and detailed reports. Equipped with dual heat flux transducers, instrument ensures precision and sensitivity in monitoring heat flow to and from specimens. Calibration with reference materials of known thermal conductivity enhances accuracy, while various calibration options further boost precision.

In addition to measuring, hardware and software enable the determination of specific heat capacity, providing a comprehensive analysis of thermal properties. Furthermore, the instrument prioritizes resource conservation with Eco-Mode, allowing for energy-saving standby and quick measurement startup in Idle-Mode. Users can easily customize activation timings using the scheduler, promoting efficiency in operations.

Key Technical Data HFM 446 Lambda Eco-Line Medium

General Information

Standards ASTM C518, ISO 8301, JIS A1412, DIN EN 12667, DIN EN 12664*

Type Stand-alone, with integrated printer

Thermal conductivity range

∙Medium: 0.002 to 2 W/(m·K)** ( achievable with optional instrumentation kit,

Performance data:

∙Accuracy: ± 1% to 2%

∙Repeatability: ± 0.25 %

∙Reproducibility: ± 0.5%

→ All performance data is verified with NIST SRM 1450 D (thickness 25 mm)

Plate temperature range -20°C to 90°C, optional for the HFM 446 Lambda Medium: -30° to 90°C

Air-tight system Sample compartment with possibility to introduce purge gas

Metering area heat flux transducer ∙ Medium: 102 mm x 102 mm

Chiller system External; constant temperature setpoint over plate temperature range

Plate temperature control Peltier system

Plate motion Motorized

Plate thermocouples Three thermocouples on each plate, type K (two extra thermocouples with instrumentation kit)

Thermocouple resolution ± 0.01°C

Number of setpoints Up to 99

Specimen sizes (max.)

∙Medium: 305 mm x 305 mm x 105 mm

Variable load/contact force

∙Medium: 0 to 1930 N (21 kPa on 305 x 305 mm²)

Force-controlled adjustment of the contact force or the desired thickness, and

thus density, of compressible materials

Thickness determination ∙Automatic measurement of mean sample thickness

∙ Four-corner thickness determination via inclinometer

∙Compliance to non-parallel specimen surfaces

Thickness measurement accuracy ∙ ± 0.1 mm

Thickness measurement resolution of the measurement transducer ∙ 0.001 mm

Software features

∙ SmartMode (incl. AutoCalibration, report generation, data export, wizards,

user methods, predefined user definable parameters, user-defined parameters,

cp determination, etc.)

∙ Storage and restoration of calibration and measurement files

∙λ90/90 Report

∙Plot of plate/mean temperatures and thermal conductivity values

∙Monitoring of heat flux transducer signal

∙Creation/selection of configurations for stand-alone-operation (without PC)