This Spring we have special offer! You can test Memmert constant climate chamber HPP110eco in your own laboratory or production!

This climate chamber is perfect for stability studies according to ICH guidelines, stability tests for cosmetics and foods as well as environmental testing and material testing. This climate chamber ensures uniform and stable temperature and humidity distribution.

We bring the demo unit to you, we show how it works, and you can to test it up to two weeks. If you like it and want to purchase it, we can offer also a special price!

The offer is valid only in Estonia, Latvia and Lithuania.

-

-

Nanosurf, atomic force microscopy systems – welcome!

We are thrilled to introduce Nanosurf as our newest partner! This collaboration brings exciting opportunities to professionals where nanoscale precision is essential.

Since its founding in 1997, Nanosurf has evolved to a global leader in atomic force microscopy (AFM). Nanosurf innovative AFM platforms are known for their accuracy, ease of use, and adaptability, serving both academic research and industrial applications in life sciences, materials science, and beyond.

Nanosurf instruments enable high-resolution imaging, force measurement, and manipulation on a nanometer scale, meeting the stringent demands of industries that rely on precise surface characterization.

With cutting-edge solutions for both research labs and large-scale industrial production, Nanosurf continues to push the boundaries of nanoscale technology.

Explore Nanosurf AFM Product Portfolio HERE.

See how AFM works HERE.

-

Trust the best Climate and Temperate Control Units

Memmert is one of the best and most trustworthy in the sector of laboratory ovens, climate chambers and incubators. Following Examples bring out the Key Advantages of Memmert units.

Rapid and gentle vacuum drying

The vacuum drying oven is reliable, comfortable and energy-efficient. Separately adjustable and directly heated thermoshelves ensure precise temperature control and, thanks to the digital pressure control, the chamber load is not only dried at high speed but also extremely gently in powerful and robust vacuum drying oven.

Together with the speed-controlled vacuum pump, the vacuum oven VO forms an unbeatably energy-efficient duo. The pump is perfectly tidied away in the matching base cabinet. Typical applications include powder and granulate drying, drying of cultures and probiotics, preservation and dehydration of food and the drying of electronic components.

Key advantages:

Intelligent direct heating via thermoshelves with calibration function.Short process times thanks to digitally controlled vacuum cycles.Enormous energy saving due to stepless adjustable vacuum pump.Longer service life of the pump diaphragm.

HPPeco - a new dimension of energy efficiency and precision

This powerful climate chamber with Advanced Peltier Technology works around 90 % more energy efficiently than compressor-cooled devices, does not require any refrigerant and is therefore easy to maintain.

The temperature range from +0 °C to +70 °C as well as the active humidification and dehumidification from 10 % to 90 % rh offered by the HPPeco are optimally tailored to meet the requirements of stability tests in compliance with ICH-Guideline (Q1A). The device is also suitable for durability tests in the fields of pharmaceuticals, food and cosmetics as well as for quality tests and humidity-controlled storage.

Key advantages:

Maximum energy efficiency compared to climate chambers with a compressor.Absolutely homogeneous distribution of temperature and humidity.Reliable and fail-safe, even after years of continuous operation.

IPPeco - sets standards for cultivation below room temperature

The cooled Incubator IPPeco with Advanced Peltier Technology is extremely energy-efficient and, simultaneously, and one of the most powerful cooled incubator of its kind. Compared to similar appliances, its heat-up, cool down and recovery times are much shorter.

The Peltier-cooled incubator from Memmert saves on operating costs, ensures sample quality and makes work in a microbiological laboratory significantly more efficient. Common applications are microbiological analyses, bacterial count determination, cultivation above and below room temperature, accelerated aging test, or shelf life tests of dairy products.

Key advantages:

Maximum energy efficiency compared to cooled incubators with a compressor.Absolutely homogeneous distribution of temperature.Greater range of application thanks to cooling down to the freezing point.

EMPOWER YOUR ELECTRONICS BUSINESS

Memmert offers you the best benefits and solutions.

Memmert is your trusted ally in the electronics sector. Their devices such as the humidity chamber HCP, the universal oven U series and the vacuum oven VO offer premium solutions for a great variety of applications within the electronics industry.

Memmert cutting-edge devices, are suitable for:

Gentle vacuum drying of intricate electronic assemblies, such as printed circuit boards, after intensive washing.Annealing or baking of electronic and mechanical components to enhance their properties.Achieving bubble-free fusion of potting compounds using our Vacuum Oven (VO).Ensuring optimal climatic conditions for the storage of electronic components as well as for conditioning, ageing and corrosion tests.Additionally, Memmert equipment can be used for precision temperature control in various laboratory processes, such as polymer curing or material testing.

-

Glass Oven G-300: The multipurpose solution for small samples

BUCHI’s Glass Oven G-300: The ultimate chemistry companion.

BUCHI has launched the Glass Oven G-300, a new and improved version of the multi-functional instrument developed with chemists and educators in mind.

Its versatile design and user-friendly features make it an invaluable tool, whether learning the fundamentals of chemistry or driving breakthroughs in pharmaceutical research.

The G-300 combines thoughtful engineering with practical features. It is perfect for small samples and has interchangeable configurations to enable drying, sublimation, freeze-drying, and distillation, allowing researchers to pivot seamlessly between applications.

The clear glass tube offers visual feedback, and its intuitive interface makes it accessible to beginners while meeting the high standards of professional labs. The Glass Oven G-300 empowers chemists to focus on what truly matters: advancing science, solving challenges, and exploring possibilities.

-

News from NETZSCH - DSC 500 Pegasus®

The DSC 500 Pegasus® High-Temperature Differential Scanning Calorimeter sets the standard for precision for DSC analysis, even at the highest temperatures. Designed for the investigation of high-performance materials, it provides solutions to complex challenges in thermal analysis.

Modular Design for extensive Versatility: Our modular design allows for easy exchange of furnaces and sensors, making the instrument adaptable to different applications. This system operates over a wide temperature range from -150°C to 2000°C to meet a variety of thermal analysis requirements.Superior Sensor Technology for Precise Measurements: Our high-performance heat flux DSC sensors, combined with precise sensor positioning, ensures exceptional accuracy for demanding applications, including specific heat measurements at high temperatures.Vacuum-Tight Design for Elimination of Atmospheric Influences: Our vacuum-tight design, combined with precise gas flow control, enables accurate management of high-purity atmospheres, including inert, oxidizing, reducing, and corrosive gases. By eliminating the possibility of unwanted reactions, this design supports reliable results.Versatile Hardware and Intelligent Software for Efficient Research: Our DSC includes a dual-hoist system that supports the operation of two furnaces or an integration of our Automatic Sample Changer (ASC), capable of handling up to 20 samples. Complementing this hardware is our superior software suite, including AutoEvaluation for automated data analysis and Identify for advanced material identification. This setup streamlines sample processing, optimizing research workflows and saving valuable time.Beyond Standard DSC Analysis: Our DSC system goes beyond traditional thermal analysis by enabling coupling with evolved gas analysis systems such as FT-IR or Mass Spectrometers. This integration significantly enhances the depth of information available from a single analysis, providing detailed insights into gas evolution and material behaviour during thermal processes.Read more about Netzsch DSC 500 Pegasus® and DSC method in attached leaflet or NETZSCH homepage.

-

New Perten Aquamatic 5300 Grain moisture meter

The Aquamatic 5300 is third-generation high-frequency moisture meter employing Unified Grain Moisture Algorithm (UGMA) technology. It can serve as a standalone moisture meter for use at terminals or can be integrated into automated testing systems.

With its high frequency, the analyzer penetrates deep into samples for improved results, while the updated UGMA provides a more accurate analysis, regardless of temperature or crop type. The improved mechanisms come together to make it the most repeatable moisture meter available – and with 10,000 meters in the field, one of the most tested and trusted. The Aquamatic 5300 system is perfect for analyzing grains, oilseeds, pulses, beans, lentils, seeds, and more for moisture, test weight, and temperature.

The beauty of the Aquamatic 5300 is in the details. Here are a few that set the system apart:

Accuracy and repeatability are achieved using a 150-MHz measurement cell made of robust, high-precision die-cast aluminum. The new cell is large enough to provide a representative sample for the measurement.Older moisture meters can read 1% to 2% low in moisture when analyzing grain straight from the field (the rebound effect). Our higher frequency measurement goes deeper into the grain, providing accurate results and faster return on investment.Just pour the sample and the system begins analysis automatically. Results are displayed in less than 10 seconds. -

Rotavapor® R-80 system: Evaporation on the smallest footprint

BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added the R-80 Rotavapor® System to its portfolio. This entry-level instrument offers BUCHI quality at an affordable price and ensures the efficient use of laboratory space. It also leads the way for more environmentally conscious evaporation solutions.

As the first company to commercialize the rotary evaporator, BUCHI has remained the market leader for many decades. Having introduced numerous innovations over the years, the R-80 is the latest in a long line of revolutionary instruments. The R-80 maintains many of the advanced features that have become synonymous with the BUCHI brand but in a format that takes up less space, uses less energy, and puts less strain on budgets.

The compact R-80 saves valuable laboratory space and opens the world of rotary evaporation to individuals and institutions that may not have the resources for larger models or those requiring a more compact and cost-effective solution without compromising quality and efficiency.

The Rotavapor® R-80 can easily be expanded with the addition of a vacuum pump V-80/V-180, vacuum interface I-80/I-180, and high-quality glassware for different needs. Available in three standard configurations:

R-80 StandaloneR-80 + Vacuum solution V-80 with Interface I-80 for manual vacuum controlR-80 + Vacuum solution V-180 with Interface I-180 for automatic vacuum controlThe speed-controlled vacuum solutions offer near-silent vacuum generation and reduced bumping. The interfaces I-80/I-180 provide an easy means of vacuum monitoring and control and can be attached directly to the Rotavapor®, the pump, or a lab stand.

To address environmental concerns, an optional valve unit can control the water flow and save resources by stopping after distillation or by a timer.

Every part of the system has been intelligently designed for user convenience and effortless operation. The central user interface can be rotated by 90° for easy access and has one central navigation control button. The smooth manual lift ensures effortless operation, while the cableless bath allows hassle-free emptying and refilling.

With a versatile heating bath with a maximum working temperature of 95 °C and the ability to accommodate flask sizes of up to 1L, the R-80 is the ideal companion for chemical research.

The Rotavapor® R-80 complements BUCHI’s comprehensive range of evaporation solutions. BÜCHI Labortechnik AG remains dedicated to offering solutions catering to all budgets and workflows of academic, pharmaceutical, chemical, and biotechnological industries.

-

New Lyovapor™ L-250: green and effective freeze drying solution

The New Lyovapor™ L-250 is here!

We are proud to introduce our new Lyovapor™ L-250 with EcoStream™ technology: the greenest freeze-drying option for your laboratory. The L-250 embodies BUCHI's commitment to enhancing the sustainability of laboratory processes. Our innovative cooling technology reduces the instrument’s environmental footprint without compromising our commitment to quality and reliability.

Like all instruments in the Lyovapor™ line, the L-250 guarantees a stable condenser temperature that allows for complete solvent collection, even for large sample batches

Thanks to these innovations, the L-250:

Can achieve a condenser temperature of -85 °C with our groundbreaking compressor design.Has a low global warming potential (GWP) of 4, with natural coolants reducing the environmental impact.Can lower the amount of heat output and noise emissions in your lab.The Lyovapor™ L-250 comes in basic or pro configurations with touchscreen controls and a wide range of drying chambers for basic and advanced processes.

Whether your samples need to be dried in flask or in vials containing formulation , the Lyovapor™ L-250 is tailored to meet your needs while pushing the boundaries of sustainable innovation.

Whether you’re a small research facility or a large-scale industrial laboratory, the Lyovapor™ L-250 is tailored to meet your needs while pushing the boundaries of sustainable innovation.

The new Lyovapor™ L-250 is a leap forward in sustainable laboratory practices.

Be Effective, Be Green, Choose Lyovapor™ L-250.

-

The New NETZSCH Thermobalance TG 309 Libra®

Netzsch has launched next generation of thermogravimetric analyzers (TGA) - the new TG 309 Libra®!

𝗢𝗻𝗲 𝗧𝗚𝗔 𝗦𝗲𝗿𝗶𝗲𝘀, 𝗧𝗵𝗿𝗲𝗲 𝗜𝗻𝘀𝘁𝗿𝘂𝗺𝗲𝗻𝘁𝘀: Choose the perfect instrument for your individual needs:

With its exceptional price-performance-ratio, the 𝗧𝗚 𝟯𝟬𝟵 𝗟𝗶𝗯𝗿𝗮® 𝗖𝗹𝗮𝘀𝘀𝗶𝗰 is the perfect instrument for quality control and education. It comes with temperatures up to 1025°C and a choice of illuminated front panel or display.𝗧𝗵𝗲 𝗦𝗲𝗹𝗲𝗰𝘁-𝘃𝗲𝗿𝘀𝗶𝗼𝗻 offers unmatched versatility, allowing an ideal configuration to meet your individual needs in both hardware and software. With temperatures up to 1025°C or 1100°C and a large Automatic Sample Changer (ASC), it is the perfect instrument for industrial research and contract testing.The 𝘁𝗼𝗽-𝗼𝗳-𝘁𝗵𝗲-𝗹𝗶𝗻𝗲 𝗧𝗚 𝟯𝟬𝟵 𝗟𝗶𝗯𝗿𝗮® 𝗦𝘂𝗽𝗿𝗲𝗺𝗲 has been designed to meet the highest performance requirements, making it ideal for research and development in industrial and academic environments.Watch short video to learn more about its unique key features.

-

Pure Essential Chromatography System: First steps to fast separations

BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added the Pure Essential Chromatography system to its portfolio. This instrument serves as the ideal introduction to automated flash chromatography. Benefitting from an easy-to-use, compact, and modular design that allows the system to grow with your needs.

The most basic of all chromatography systems is the traditional open-column setup. It is how most people are introduced to chromatography, similar to the setup used by chromatography’s inventor Mikhail Tsvet. The setup is very basic, involving a glass column with two open ends. At the bottom of the column is a stopcock to control the solvent flow directed to the collection flask. The entire process is gravity fed; therefore, it is slow and inefficient and requires someone to perform each step of the separation process manually.

Over the years, the technique for separating compounds of synthesis or extraction mixtures has been vastly improved; however, many modern systems are complex and expensive and offer advanced features that some users do not require. The Pure Essential Chromatography system has been specifically developed to fill this gap in the market. At its heart is a strong 50 bar pump that allows for high flow rates. The pump rapidly moves the solvent and sample through the stationary phase. The instrument allows for automation of the process thanks to an intuitive software control which also ensures fast and reproducible results. Only a few clicks are required to program a method or adapt parameters on the fly. Prepacked flash cartridges simplify the setup, as there is no requirement for manual column packing. The entire system is efficient and uses small particle sizes for higher-resolution results, all while reducing solvent consumption.

The Pure Essential Chromatography system has been designed as a modular system with a small footprint, allowing the setup to grow with your needs. A highly sensitive UV detector or fraction collector can be added to the powerful Pure Chromatography C-900, a controlled pump. Safety is also a key feature of the Pure Essential Chromatography system which is equipped with a pressure sensor and benefits from a solid design with steel pump heads and robust accessories built for the rigors of daily use. Everything is easily accessible on the instrument, making maintenance a breeze.

Simplicity results from intelligent design and years of experience, and the Pure Essential Chromatography system is a shining example of a dedicated focus on perfecting the essentials. The instrument is ideal for academia or labs that require a bespoke setup for a particular workflow. “The Pure Essential Chromatography system is super easy to use, without any bells and whistles. It benefits from a small footprint and attractive price as well; it is the perfect way to enter the preparative chromatography instrument world when used to using open columns,” said Dr. Ruedi Hartmann, Director of Business Areas & Vertical Markets at BÜCHI Labortechnik.

The Pure Essential Chromatography system completes BUCHI’s comprehensive range of preparative chromatography systems. BÜCHI Labortechnik AG remains dedicated to offering solutions catering to all budgets and workflows of academic, pharmaceutical, chemical, and biotechnological industries.

-

BeamPeek – Full Beam Analysis system under 3 seconds

Ophir is happy to announce the release of the new BeamPeek.

The BeamPeek™ system allows simultaneous beam profiling, focal spot size and position, and power measurement of Additive Manufacturing (AM) lasers. It tracks how those parameters change with time to assist in the maintenance of quality and repeatability of the manufactured parts. The BeamPeek™ integrates a laser beam profiler camera, power meter, beam dump, beam splitters, and optics to provide an all inclusive solution for additive manufacturing laser analysis in an industrial environment.

Focal spot sizeFocal spot position calibrated to build planeLaser powerLaser power densityChanges in spot size & power over timeYou can find more information here.

-

New Memmert overview brochure

Now available - new overview brochure of Memmert products.

Memmert product line includes constant climate chambers, heating and drying ovens, incubators, medical devices and water baths.

With the current product range brochure, you have an excellent overview of all Memmert products in one handbook and can quickly and easily check which device is best suited for a customer's application.

The QR code for each model leads you directly to Memmert website with detailed information.

Take a look at Memmert new product range brochure and make your decision in the right device even faster and easier.

We will gladly help you choose the most suitable equipment and provide a full service. Contact us if you have any questions.

-

New porometer/fluorometer from LICOR

The LI-600 is a compact porometer with an optional Pulse-Amplitude Modulation (PAM) fluorometer that measures stomatal conductance and chlorophyll a fluorescence over the same leaf area. Capable of completing a measurement in seconds, the LI-600 provides the speed and precision required by researchers today.

How its different? The LI-600 is designed to quickly survey plants under ambient conditions. You can configure the instrument to log a measurement automatically when parameters are stable, or you can log manually with the press of a button.

Time-saving features for fast surveys

Automatic logging to complete a single measurement in seconds, typically.Simple, intuitive display shows the instrument status and most recent measurement.Ergonomic and light weight for easy handling.Barcode scanner to enter sample information and reduce manual data entry errors.Built-in rechargeable battery provides 8 hours or more of active use.Software that simplifies your work

You can configure the LI-600 with ease – just set a few parameters in the computer software and you are ready to collect data. Each LI-600 can store up to four configurations, making it easy to switch from one protocol to another. You can save numerous configurations on your Mac or PC and share configuration files with colleagues. Configurations are easily loaded from the software onto the device through a USB connection.

Whether you are preparing for measurements, evaluating data files, or verifying the calibration, the computer software presents a simple, intuitive interface that lets you focus on the task at hand.

Read more from LICOR homepage. Or look the brochure.

LI-600 -

Automated microscopy testing tailored to your individual needs

The brand-new HPPCeco-AMI offers you a complete solution for a continuous monitoring of samples under controlled climatic conditions. What’s more, it’s done without the need to remove specimens from the device. The combination of intelligent imaging and ambient monitoring enables a precise automated evaluation of samples whilst minimising the risk of human error and providing reproducible results. With round-the-clock automation, controlled environmental conditions and availability of digital data, the system provides an efficient solution for long-term studies and quality assurance purposes.

Automated microscopic imaging – inside the climate chamberThe solution offered by m360 is based on an intelligent imaging module from the company Opto. This imaging module is capable of capturing high-resolution microscopic images of samples from within the Memmert climate chamber – even during ongoing tests. This seamless integration of imaging and precise climate control enables a continuous and reliable monitoring of your samples.

Advanced AI-supported image analysisThe generated images are automatically transferred to an advanced software developed by the company Opto. Using artificial intelligence, the system converts the raw data into false-colour images and analyses the development of the specimen. This, for example, makes it possible to document cell confluency – the seamless coverage of the surface of a culture dish by adherent cells – over a period of time with precise percentage values. The images are saved along with timestamp, details of ambient conditions and AI-supported software evaluation.

Particularly noteworthy: The door of the device does not need to be opened for microscopic examination during the ongoing test. This eliminates the risk of sample contamination and fluctuations in temperature.

The solution is ideal for a wide variety of applications including:The benefits of this integrated system are manifold:Round-the-clock automation; no manual handling required.Avoidance of ambient fluctuations during the monitoring process thereby ensuring a consistent and stable environment.Minimisation of the risk of contamination by eliminating the need for sample removal.Reduction in the level of human error resulting in improved quality assurance.Possibility for automatic sample evaluation thus saving time and increasing efficiency.Assurance of reproducible results, crucial for long-term studies and quality control processes.Digital availability of all data enables easy archiving, tracking and analysis for research and quality assurance purposes.Technical details of the climate chamberThe Memmert climate chamber HPPCeco-AMI offers temperature settings from +0 °C to +70 °C and a humidity range from 10 % rh to 90 % rh making it ideally suited for stability tests in the pharmaceutical industry, e.g. ICH guideline Q1A. Further typical areas of application include shelf-life tests in the pharmaceutical, food and cosmetic sectors and quality control testing for different kinds of components.

What’s more, the HPPCeco-AMI offers active CO2 control from 0% to 20% thus expanding the range of applications to include the cultivation of living cultures such as bacteria and fungal strains in the pharmaceutical and biochemistry sectors.

Key advantages:

Absolutely homogeneous distribution of temperature and humidity.Reliable and fail-safe – even after years of continuous operation.Always a good climate: quiet, compact, low-maintenance.Technical details of the digital microscopesOpto digital microscopes (imaging modules) bring an unprecedented level of user-friendly and easy-to-integrate imaging performance to any production environment – from measuring machines and inspection systems to bio-imaging instruments.

Each module comes complete with its own SDK and comprehensive free image capture software, so it can be easily integrated into any existing network or system.

High-resolution, perfectly matched optical designs with latest image sensors and high-performance LEDs in a compact aluminium housing.USB3 or GigE interface with compatibility to most image processing libraries.Ultimate image quality, easy integration, guaranteed performance in any application.Powerful imaging with simple plug-and-play functionality.Enhanced image quality thanks to perfectly matched component selection.Robust aluminium block design with different mounting options.Includes OptoViewer and various application plug-ins.Software integration tools: C/C++ OptoSDK, NI LabVIEW Toolkit, NI Vision Builder Plugin.

About OptoOpto, based in Munich/Germany, is one of the leading manufacturers of digital microscopes for both standard and customised series production. These imaging modules are specifically designed for machine integration in medical technology and industrial applications. They provide image data that can be reproduced anytime and anywhere, making them ideal for any automation task.

Imaging modules are robust vision sensors with integrated camera, optics, lighting and electronics. Over the past 40 years, Opto has succeeded in establishing itself as an international OEM supplier focusing on microscopy and industrial image processing.

-

Ask An Expert: Advanced Dynamic Light Scattering: When can a polarizer give you extra insight?

Dynamic light scattering (DLS) is now a ubiquitous tool in many laboratories, and offers an accessible and accurate way to find hydrodynamic size in minutes. The non-invasive technique requires very little sample and is quite easy to use for a range of user abilities. But did you know that in certain situations a polarizer or a fluorescence filter can give you even ‘more’ data? As it turns out, the backscattering detection feature of the Zetasizer is less well-known than we thought, so in this webinar Dr. Ulf Nobbmann will share his insights into how you can get the most out of your DLS instrument – and your analysis.

When

23.november. Starting 16:30 CET.

Who should attend?

Anyone who wants deeper insights into more than the standard application of DLS for particle size;Anyone interested in or working on quantum dots, fluorescently

labelled particles, or similar research areas;Scientists and researchers interested in understanding advanced

capabilities of light scattering.What will you learn?

Learn how to configure the polarizers and fluorescence filter in the Zetasizer;Discover how parallel and perpendicular polarization correlationfunctions may differ;Understand why these may differ in intercept & measured size. -

Memmert - 90 years of being ahead

From Schwabach into the big wide world

When Willi Memmert and his wife Eva-Babette Memmert opened the doors of their small electrical business in their hometown of Schwabach over 90 years ago, they had no idea that 15 years later they would have dealings with customers on the other side of the planet. Nor did they imagine that they would be cooperating closely with associates in India and Egypt in order to expand their business interests there and lay the foundation for future long-term partnerships. What’s more, all without speaking a word of English. Nonetheless, the entrepreneur Willi Memmert was convinced that there was a market for his flagship product beyond the borders of Germany and he fully intended to tap into it.

Founder of Memmert GmbH + Co. KG: Willi Memmert

The foundation for success

In 1947, the trained electrical engineer was commissioned by the Red Cross to manufacture a hot-air steriliser – the ‘Aeolus’. It was used to keep syringes and other medical equipment germ-free thereby playing an active role in curtailing epidemics and diseases. The success proved the company founder right: by the mid-1950s, the company Memmert was already exporting its appliances internationally.

Then we’ll just have to improvise…

This is just one of many examples that illustrates the role improvisation and practical organisational talent has played on Memmert’s journey from small family business to globally operating enterprise, today exporting to more than 160 different countries around the world. It was also this pragmatic approach that resulted in the development of the ‘Aeolus’ back in 1947. In those days, raw materials were scarce. Willi Memmert therefore built the prototype from recycled aluminium from old aircraft parts.

First Memmert hot air sterilizer: Aeolus

“Here’s what we need: …”

“Our developments are responses to the suggestions and requirements of our customers,” says Christiane Riefler-Karpa, the company founder’s granddaughter and managing director since the year 2007. “We deliver the solutions.” Having initially served the medical segment with its forerunner ‘Aeolus’, the company Memmert gradually began to receive more and more enquiries from a wider variety of industries. Whether research, pharmaceutical, cosmetics or foodstuff industry: throughout the era of economic miracle, the demand for accurate climate and temperature control technology was high. The innovation cycles of the originally small family business became increasingly shorter.

Aeolus and other milestones

The cornerstone of the company's success was the ‘Aeolus’. This was followed in the 1950s by another milestone: a mechanical controller which, for those days, offered exceptionally high precision. The temperature could be set via a control knob with an accuracy of less than ± 0.5 °C. Equally as revolutionary: the world’s most accurate temperature control appliance with all-round heating system – the first product launched by the future global player.

This was a technical innovation with heating coils placed in pressed swages in its inner chamber which meant that, for the very first time, it was possible to construct a heating oven that wasn’t round, but square – which made it infinitely more practical.

The following decade saw a drive for the establishment of a series production to enable the output of significantly higher quantities. The 1970s and 80s focused on automating manufacturing methods and perfecting product design.

In 1976, management of the company was passed on to the next generation. Daughters Grete Memmert-Riefler and Herta Ulrich and their respective husbands took over leadership of the firm after the death of Willi Memmert. They recognised the potential offered by advancing globalisation and paved the way for their open-minded company to tap into new markets all over the world.

A new breakthrough every ten years

This was the era in which Memmert again brought an absolute innovation in temperature control technology onto the market: as one of the first manufacturers worldwide, Memmert complemented its product range with in-house developed electronic controllers. The next time Memmert took on a pioneering role within the industry was in the year 2000, when it launched the first cooled incubators with Peltier technology. Not only does this technology offer top accuracy in the operation of climate and temperature control appliances, it is also highly impressive when it comes to energy efficiency and cost-effectiveness.

Particularly noteworthy are the two device generations from 2003 and 2012 which were instrumental in defining industrial standards in terms of functionality, accuracy and ease of use for both laboratory and industrial applications. It therefore comes as no surprise that Memmert is celebrating this year's anniversary under the motto '90 years of being ahead'.

Into the future

Meanwhile, Memmert ovens have arrived in the future. A specially developed software enables the latest generation of appliances to be programmed remotely and networked with one another. From afar, from a home-office desk, with a tablet, from anywhere in the world. Another logical development, which resulted not least from the increasingly networked nature of the company itself: in 2010, Memmert established a distribution company in China, followed by another one in India in 2012. More have followed in the USA and Eastern Europe. There are separate teams for Germany, France, Spain and the United Kingdom. "We maintain relationships with many of our customers that go back decades, in some cases over generations," says Christiane Riefler-Karpa. "The trust our customers place in us is the most valuable aspect of our company's capital." And it is for these customers that Memmert will continue to give its best in the future.

Air view of production site in Buechenbach, Germany -

NanoSight Pro Launch 15th of June - new device to visualize and measure nanoparticles

Be part of the introduction of the next generation Nanoparticle Tracking Analysis (NTA): The NanoSight Pro.

During this event you will see that characterizing Bionanomaterials has never been so quick, easy and accurate. In a live session from a studio in Worcester, the new NanoSight Pro will be revealed by a special host who has a long history in NTA. After the reveal, we will share the first experiences from our customers to give you insight into the possibilities and benefits of this new instrument. You will learn how the combination of new software and its unique optical heart brings new dimensions to repeatable detection and superior data quality. Our customers will also give insight into how the blend of smart features and machine learning removes subjectivity and human error, making particle tracking even quicker and more accurate. We end the session with a demonstration of the instrument and give you the opportunity to ask questions.

Who should attend?

For early-stage R&D scientists and technicians working in Pharma and interested in characterizing bionanomaterials and nanoparticlesIndustrial: Head of Department (TBI and EBI)Academic: Professor (UBI and EBI)Academic or Industrial: Researcher (UBI and TBI)For early-stage R&D scientists and technicians who need easy access to high resolution size and concentration data for the characterization of bionanomaterials, the Malvern Panalytical NanoSight Pro is a self-installed, (automated) platform which is accessible to all levels of user, removes subjectivity, and provides more intelligent size and concentration data, more quickly when operating in both Standard (scatter) mode and in Fluorescent mode.

What will you learn?

Learn how the NanoSight Pro:

Provides a platform that is accessible to all levels of usersRemoves subjectivity,Enables automated measurements and provides the best and most detailed size and concentration data in the quickest possible way.Get you the most accurate identification and tracking of nanoparticles providing high resolution size and concentration dataProvide you automated processing and quicker analysisImproved sensitivity to confidently measure low scattering and biological particlesGreater insides into sample subpopulation with the improved fluorescence detectionWill get you up and running quickly with smart installRegister here

Short overview about previous generation Nanosight. In 90 seconds:

-

Memmert promotes Domagroup companies to Premium A level partner in Baltics

Domagroup companies (Est-Doma OÜ, SIA Doma and Vildoma UAB) have earned an upgrade to Premium A partner level and preferred representative role from Memmert (Germany), a producer and developer of temperature and climate control products. Domagroup has been providing and supporting Memmert products in Baltics already for more than 25 years and it has grown into a trustful relationship with common objectives.

Experience, knowledge, and competence of Domagroup employees has allowed to enhance work for many customers in Baltics with Memmert products. Domagroup employees are continuously learning and improving their knowledge about Memmert products to continue to provide high quality technical support and consultation for customers.

Memmert and Domagroup cooperation gives more possibilities to customers, including also custom-made solutions created by Memmert M360 division. Being Premium A partners, Domagroup employees will be able to provide to customers:

Latest information about Memmert products;User training;Support for technical issues;Access to support from manufacturer;Custom-made solutions;3 years warranty period.Domagroup, as experienced product integrator, will be happy to provide customers with full solution systems that can cover complex processes and functionality requirements.

This year Memmert is celebrating its 90th anniversary and to mark this occasion there will be special offers by Domagroup for Memmert product orders throughout the year. Contact the local Domagroup office to see what benefits Memmert products can bring.

Domagroup has been offering laboratory and measuring instruments since 1991. Current portfolio covers a wide range of laboratory supplies, including measuring instruments, lab equipment, consumables, etc. as well as educational equipment for engineering and natural sciences. Domagroup aims to enhance the work of researchers and scientists with high quality instruments and solutions.

-

Sepiatec SFC Systems - the green standard for fast compound isolation

BÜCHI Labortechnik AG, a leading provider of laboratory equipment, has added Sepiatec SFC, its first Supercritical Fluid Chromatography (SFC) systems, to its preparative chromatography portfolio. Thanks to smart system design and substantial reductions in organic solvent use, the Sepiatec SFC line enables a more efficient and eco-friendly purification performance.

The SFC method is demonstrably faster than prep HPLC. This type of chromatography has shorter run times thanks to the low viscosity of supercritical fluids used as mobile phases. High separation efficiency can be readily achieved, allowing for increased loading capacity and fast injection cycle time, speeding up the process even more. Time is also saved due to quicker solvent disposal and recovery.

The Sepiatec SFC instruments are designed to make a wide variety of applications possible. With a broad range of pump flow rates, column sizes and lengths, compatibility with UV, ELSD and MS detection, options for stack or multiple injections, fraction collection without limitations on volumes and the possibility to operate the system on the benchtop or in a fume hood, operators are free to customize their system to their needs.

Sepiatec SFC systems advantages:

Safety and sustainability – low-toxicity carbon dioxide as a mobile phase reduces exposure to hazardous solvent.Speed and productivity – faster run times, stack injection loading, and easier solvent handing for more productive use of your time.Cost-efficiency – substantial savings as no purchasing, recycling, storing and disposal of organic solvents is needed.The Sepiatec SFC product line joins BUCHI’s established portfolio of preparative chromatography solutions. Together with systems for flash chromatography & prep HPLC, chromatography columns, cartridges and accessories, BÜCHI Labortechnik AG continues to support customers in the pharmaceutical, chemical and biotechnological industries in their efforts to maximize efficiency while achieving highest compound purity.

More information about Sepiatec SFC systems you can find here.

-

The next-generation spray dryer has arrived!

Experience spray drying like never before with the revolutionary Mini Spray Dryer S-300.

The instrument’s advanced automation and design features position it as the only spray drying system of its kind. Backed by more than 40 years of spray drying experience as the leading global provider of spray drying lab equipment, BUCHI has re-invented the spray dryer to improve your performance in ways you never thought possible. You are now one spray dryer away from a spray drying process that is remarkably MORE user-friendly, reproducible and efficient!

The Mini Spray Dryer S-300 offers you unique features you cannot find in any other spray drying equipment.

Improved reproducibility:

Automatic system regulation of spray drying parameters, such as spray gas, drying gas and pump speed.Automatic system monitoring of outlet temperature and product temperature, especially important for heat-sensitive samples.Conductive coating of cyclone to reduce sample from sticking to the walls.Stainless-steel spray drying nozzle strengthened with a ruby stone.Improved spray drying experience:

Auto mode for a fully automated spray drying workflow.Method programming options to save and repeat runs, process one sample after another automatically.Printing of reports in different formats by pushing one button.Remote monitoring and control of the spray dryer via an app on any mobile device or computer.Effortless system maintenance and cleaning, as cyclone can be easily taken apart.Safe handling of organic solvents:

Inert Loop S-395: safely spray dry samples with organic solvents where the nitrogen drying gas is circulated, the solvent is collected as condensate and the oxygen level and gas flow in the system are continuously monitored.Dehumidifer S-396: provides dry air to enable continuous work with water and organic solvent mixtures with stable spray drying conditions.

-

Future Days: Battery & Additive Manufacturing (virtual event, November 8, 2022)

Listen to an engaging mix of presentations and interviews in the field of advanced materials. Hear directly from our industry experts on what they consider to be the material challenges of tomorrow and find out about the solutions Malvern Panalytical can provide to meet these. This two-track event, consisting of two-hour online events, will bring you up close with our battery manufacturing and additive manufacturing experts, giving you a chance to find out the latest industry insights.

Who should attend?

Professionals working within the additive manufacturing or battery industriesWhat will you learn?

Learn more about the trends and developments in additive manufacturing and batteriesLearn how these two industries deal with sustainability and recyclingWhat does the future look like for additive manufacturing and batteriesNew possibilities for chemistry and analysis within both segmentsAsk your own questions related to batteries and additive manufacturing to our experts and join our live round table discussionAgenda (AM* - additive manufacturing. Without * - batteries manufacturing)

16.00 - 16.10 Introduction

16.10 - 16.35 Find out all the latest insights about additive manufacturing. AM* - Prof. Dr. Ian Gibson, University of Twente

16.10 - 16.35 Challenges in future battery designs. Egbert Figgemeier, RWTH Aachen University

16.40 - 17.00 Research around green hydrogen technologies. Klaus Friedel, Malvern Panalytical.

16.45 - 16.55 Exploring the role and measurement of particle size and shape for powder bed - AM*, Dr. Paul Carpinone, Malvern Panalytical XRD Technical Specialist

16.55 - 17.05 Detecting contaminants in metal powders using X-ray fluorescence - AM*. Dr. Violeta Uricanu, Malvern Panalytical XRF Application Specialist

17.00 - 17.25 Battery: Morphological and structural characterization. Dr Scott Speaksmann & Dr. Umesh Tiwari

17.05 - 17.15 Powdercleanse: An automated closed-loop powder processing system for additive manufacturing - AM*. Adam Hall, Malvern Panalytical.

17.15 - 17.25 Non-destructive testing of AM parts using X-ray powder diffraction - AM*. Nicolas Norberg, Malvern Panalytical.

17.25 - 18.00 Round Table. All experts.

-

Cooperation between SIA Doma and ClydeHSI

We proudly inform that SIA Doma has signed an agreement with Clyde Hyperspectral Imaging and Technology Ltd., (ClydeHSI) and has become the partner of the ClydeHSI in the Baltic States, opening the possibility for customers to receive wider support in this area.

SIA Doma is a company with 30-year experience providing solutions and services of a wide range of equipment, measuring instruments, laboratory, and technological equipment.

The company employs highly qualified specialists who are experienced in the implementation of simple, large, as well as complex projects. From the very beginning, the main objective of SIA Doma has been to support the growth of its customers based on technological capabilities. This new cooperation with one of the world's leading manufacturers of hyperspectral imaging systems and optical spectroscopy instruments is an important addition to our product portfolio expanding our offering to customers in the Baltic States.

ClydeHSI design and manufacture a wide range of both hyperspectral and conventional spectroscopy instruments, specialising in full hyperspectral imaging systems. All ClydeHSI products are supported by leading software for data acquisition, analysis and display.

ClydeHSI mission is to provide each and every client with a complete, end-to-end hyperspectral imaging solution, each designed and rigorously tested to ensure robust, reliable, accurate and repeatable hyperspectral imaging measurements across a range of academic and industrial applications. This synchronises perfectly with the SIA Doma mission - to create and promote the growth of our customers based on technological innovation and strong relationships. Our ultimate goal - to be a contribution in creating a society based on knowledge.

ClydeHSI Hyperspectral Systems add value by creating spatial maps of spectral features that enable identification of material components and their spatial distribution within a measured sample. This is because the spectral features identified act as a unique “fingerprint” of the material being measured, and hyperspectral imaging has subsequently emerged as a key analytical tool in a wide range of applications, as it is versatile, fast, safe, reliable, and is suitable for both laboratory studies and automated quality inspection on production lines with results in real time.

ClydeHSI have delivered systems into many different applications worldwide:

Food quality assessmentArt & art conservationForensic AnalysisChemical imagingColour measurementChange detectionIndustrial quality controlInspectionMaterials identificationMedical and pharmaceuticalsRecyclingSIA Doma in cooperation with ClydeHSI, will be delighted to help you facilitate and improve quality control, inspection and measuring processes, offering modern, high-quality, reliable, and safe solutions – according to your needs.

More information on our websites www.domagroup.eu and www.clydehsi.com

-

Vacuum drying at a new stage – the Memmert VO!

Have you ever wondered what the advantages of a vacuum oven are compared to a conventional drying oven?

With a vacuum oven, you can dry even sensitive goods precisely – especially, quickly! How does it work? The direct heating in the Memmert vacuum oven VO guarantees optimal, homogeneous temperature distribution on all levels. Innovative thermoplates transfer the heat precisely and directly to the load without heat loss. This allows you to achieve optimal drying, through vacuum, faster than ever before.

In an interview with VO expert, Heinz Bayer, find out what is a vacuum oven used for, how does a vacuum oven work – either in the white paper or take a look at specific applications with the VO. Learn more about how a vacuum drying oven from Memmert supports in research and daily work.

Immerse yourself in the world of https://www.memmert.com/blog/the Memmert vacuum ovens VO!

-

Food oil monitor set FOM 330

Food Oil Monitor Set - FOM 330

System characteristics and application:

• change frying oil at the right time;

• measures hot oil directly in the fryer;

• restaurants / canteens;

• no health risks caused by spent oil;

• fast, safe on-site measurement;

• enables setting of ideal frying point;

• exact determination of frying oil quality;

• 0 ... 40% polar compounds;

• temperature range up to 200 °C;

• limit indication by flashing light (red/yellow/green);

• with simple oil type selection with one button.

-

Wireless data logger ALMEMO® 470-1

Wireless data logger for 10 wireless sensors.Wireless ALMEMO® sensor for temperature, atmospheric humidity, atmospheric pressure. For monitoring the room air condition or with extended operating temperature range from -40 to +85 °C.Wireless ALMEMO® interface for ALMEMO® D7 sensor.For various measurable variables. Wireless ALMEMO® sensor for carbon dioxide, air temperature, air pressure.The ALMEMO® 470-1 Wireless Data Logger is a professional measuring device that receives measured values with a time stamp from up to 10 remote radio sensors, stores them and displays them graphically on a 5.7“ touch display. The data logger works in the 2.4 GHz frequency band for wireless communication. Comments can be stored in the radio sensors for optimal assignment to the individual measuring locations.

Compact measurement software is available for evaluating the measurement data.

Each radio sensor has a repeater function and can thus forward the data from neighboring sensors to the logger. It can also be used to integrate remote sensors that have no direct radio connection to the measuring device.

A market novelty is the individual adapter for connecting digital sensors for wireless measurement of a variety of physical, electrical or chemical quantities, e.g. CO2, air flow, illuminance or pH value.

Using digital ALMEMO® D7 plugs, it is even possible to digitize sensors from other manufacturers and integrate them into the radio network.

For climate monitoring there are Radio sensors for temperature (5 to 50 °C), air humidity (5.0 to 98%) and air pressure (3mm to 1100 mbar) available. A version with an extended temperature range (-40 to +85 °C) and splash protection is suitable for measurements in conditioning and climatic chambers or for environmental protection tasks.

-

GUNT 2022 overview Catalogue (engineering education)

GUNT's new Catalogue provides a quick overview of all the devices - clearly structured by product range. All devices can be quickly accessed via the integrated navigation. Further information on GUNT devices is available via direct links in the PDF.

A large number of devices are equipped with SMART features. In this way, learning can take place according to the model of hybrid learning objective development.

GUNT 2022 overview Catalogue

GUNT offers more than 500 devices for hands-on teaching engineering.

-

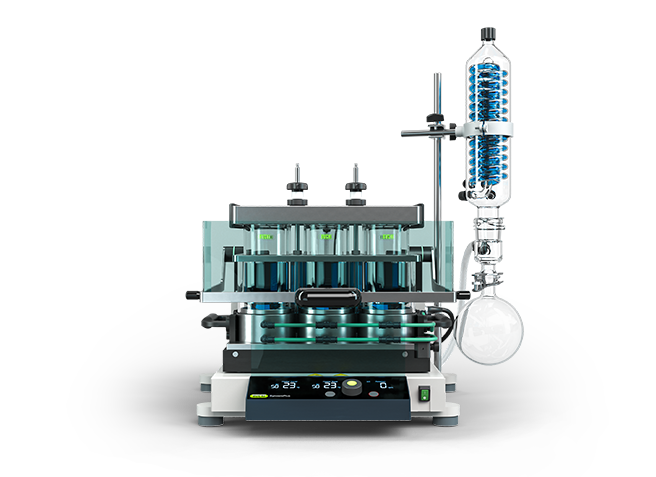

BÜCHI’s new steam distillation units offer tailor-made solutions

BÜCHI two new product lines for steam distillation with innovative, modular features provide the highest flexibility in analyte determination. The newly developed instrument is available either as BÜCHI Kjel Line or Dist Line with three different performance levels. The Kjel Line is optimized for Kjeldahl applications for nitrogen and protein determination and provide highest accuracy while saving time and resources. The Dist Line is designed to cover a broad range of steam-volatile analytes offering highest flexibility and convenience.

The new BÜCHI Kjel Line provides the most accurate and reproducible nitrogen and protein determinations thanks to advanced built-in sensor technology. The communication with peripherals such as cooling water valve, tank level sensors, safety door sensors and an innovative level sensor enable outstanding user protection and a new level of efficiency. With environmental safety in mind, BÜCHI has also developed a unique reaction detection sensor, which saves up to 30 % of reagent consumption.

The BÜCHI Dist Line sets new standards in the versatile determination of steam-volatile analytes in samples from the beverages and food industries, as well as from chemical, environmental and testing labs. The systems can determine multiple analytes such as alcohol, sulfite, volatile acids, cyanide, essential oils, phenol index, vicinal diketones, formaldehyde and nitrogen. The instruments enable more multitasking possibilities, faster method development and can be easily upgraded to a tailored solution, fitting to the customers’ individual needs.

Some new instrument features to improve process accuracy and save money:

AutoDist function: This function recognizes the start of the condensation process and adjusts the distillation start time automatically in the individual measurement.OnLevel sensor: The sensor stops the distillation automatically after a defined condensate volume is reached.Reaction detection sensor: It can save up to 30 % of NaOH reagent solution for the alkalization process so that you can work more cost-efficiently and environmentally friendly.MaxAccuracy mode: In order to avoid supply voltage deviations, a voltage stabilizer is integrated to maintain the required supply voltage. This enhances measurement accuracy and ensures highest reproducibility for every result.Steam ramps: The steam power is adjustable and steam ramps are programmable to handle foaming samples.Intuitive touch display: The intuitive touch screen provides fast feedback and enables easy process handling.BÜCHI have relied on more than 50 years of experience in steam distillation to develop these two new product lines that are designed to meet multiple customer needs, such as modular flexibility, accurate and reliable results with ecofriendly and safe procedures for both operator and the environment.

-

EBRO thermometers and data loggers new catalogues for Year 2022

New 2022 catalogues of EBRO are available only online.

EBRO offers professional instruments to measure temperature and log the measuring results. Both handheld instruments and data loggers are suitable for many applications.

Two catalogues available:

1. Professional Measurement Technology - food, pharmaceutical, laboratory, industrial.

2. Professional Data Loggers - for validation, routine control and process monitoring.

Example of professional precision thermometer

Laboratory Thermometer TFX 422C with fixed Pt 1000 probe

Measuring range -50 °C...+200 °CAccuracy ± 0.3 °CResolution 0.1 °CFactory calibration certificatesilicone cable for probePTP approvedDisplay - LCDRobust and impact resistandWaterproof IP 67Approx. 5 years battery lifePossible accessories: wall bracket, battery exchange set, carring case, stainless steel bracket, protective cover for thermometer.

Product code: 1340-5433

For other products please look the catalogues or contact us.

-

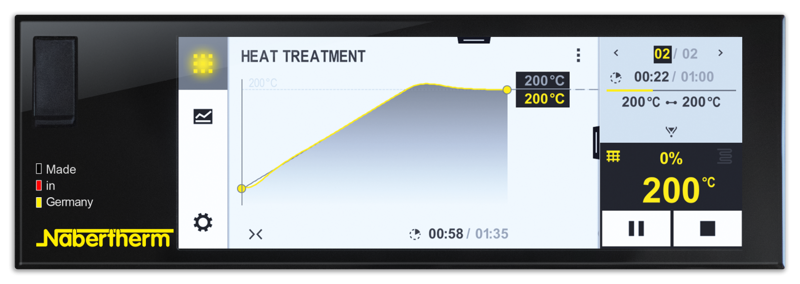

Nabertherm: The controller series 500

Nabertherm new controller with proven quality “Made in Germany” and innovative design. Naberthem want to make the operation of their furnaces as intuitive and practical as possible for you. You now not only benefit from this when operating the furnace, but also have control when you are out: with the MyNabertherm App which is available to you free of charge for every controller.

In addition to the well-known and matured controller functions, the new generation offers you some individual highlights. Here is an overview of the most important ones for you:

INTUITIVE TOUCH SCREENPRECISE TEMPERATURE CONTROLEASY PROGRAM ENTRY AND CONTROLUSER LEVELSPROGRAM STATUS DISPLAYEND TIME AND DATE DISPLAYPROCESS DOCUMENTATION ON USB24 LANGUAGESHELP MENUDISPLAY OF THE PROCESS STEPS IN PLAIN TEXTAPP: With the MyNabertherm App you always have a full overview. It can be connected to one or more Nabertherm controllers and offers direct access to the Nabertherm service.

-

All that is essential for process control

Are you interested in real-time quality control? Are you looking for a cost-effective solution with high quality standards to monitor basic parameters such as moisture, fat or protein in your manufacturing processes? The X-Sential™ is the result of more than 15 years of process experience. It was designed and engineered to be THE cost-effective and fit-for-purpose process sensor.

The X-Sential™ is:

user friendly, even without expert knowledge;cost-effective with a payback time 1 year;certified to meet the toughest testing criteria (IP69/X9K).Curious to learn why the newest member of BUCHI NIR family is essential for your process control? Discover more

-

From freezing cold to tropical heat - now also in XXL

Maximum size now with maximum temperature!

From this July 2021, Memmert will be delivering all XXL Peltier devices (HPP1400eco / IPP1400eco / IPP1400ecoplus / HPP2200eco / IPP2200eco / IPP2200ecoplus) with an extended setting temperature range.

Memmert's Peltier-cooled incubators IPPeco and the constant climate chambers HPPeco of sizes 1400 and 2200 are unique. These XXL devices are ideal for users requiring a lot of space inside. Memmert experts are constantly working on the further development of our versatile products. With the added temperature range of the HPPeco and IPPeco / IPPecoplus models, users can now enjoy greater flexibility.

You can now use the largest of the Memmert cooled incubators and climate chambers to generate extended temperatures and climatic conditions because the temperature range has been increased from the previous +15 to +60 °C to the new 0 to +70 °C. What comes standard in our smaller models is now also going into production for the Memmert giants.

What exactly does that mean? Assuming you want to expose a large amount of load to a temperature of +10 °C, you will achieve your results more efficiently in the future. Instead of using several smaller constant climate chambers or Peltier-cooled incubators, one of our XXL devices will suffice.

-

Romaco expands processing business taking over of Spanish manufacturer STE Tecpharm

With the acquisition of the Spanish manufacturer STE Tecpharm, S. L., Romaco strengthens its position as a turnkey supplier of processing technologies. In particular, Tecpharm’s patented drum coaters will complement Romaco Innojet’s granulation and fluid bed technologies.

Tecpharm's drum coaters, coupled with the company's conventional granulation lines and Wurster fluid bed systems, make a perfect complement to the Romaco range for processing pharmaceutical solids.

Tecpharm was founded by David Mateo, Bárbara Jané and Pedro Cuadrado in 2013. The company employs around 30 people at its present site in Rubí (Spain) near Barcelona. Tecpharm's core competencies as a supplier of equipment for the pharmaceutical industry comprise the development, assembly and marketing of coating systems for tablets. In addition, the manufacturer provides various technologies for wet granulation on a laboratory and production scale.

Romaco Tecpharm is today an innovation leader for perforated coating pan machines, designed to produce film coating of tablets or pellets, suitable in aqueous and organic coatings. Romaco Tecpharm's patented variable batch size Optima coater are setting new industry standards with its fully automatic batch size adjustment between 10% - 100%.

-

Weisstechnik new temperature shock test chamber ShockEvent D

With the Damper Shock, Weisstechnik is expanding its portfolio of temperature shock test chambers. The new test chamber from the ShockEvent series is predestined for test specimens, which are sensitive to vibrations or energised.

The special feature of the Damper Shock is the stationary test space. Temperature-controlled hot and cold air is generated in chambers above and below the test space. Via Dampers, the air can be led to the test specimens. This is the major difference from horizontal and vertical shock test chambers, where the test specimens are located in a test cage that can be moved between two temperature chamber.

With its static test chamber, the Damper Shock is ideally suited for vibration-sensitive measuring technology and sensor technology as well as for active test material that is to be shocked without further influences. It meets the requirements of standardised temperature stress tests such as IEC 60068-2-14, the Japanese standards JASO D-014-4 and EIAJ ED-2531B Na and various degrees of severity of MIL-STD-883H and 202G.

In addition, the new test chamber has been designed as a two and three zone shock tester, which now allows ambient air flow in. This provides more flexibility for a variety of test requirements. Another advantage of the stationary test chamber is the simple cable guiding for measuring equipment. The cables are stationary in the test space and do not move, unlike in other shock test models.

With outer dimensions of 1970 x 1595 x 1765 mm, the test chamber is used by development laboratories and quality assurance in production halls. The test space volume is 210 litres with dimensions of 700 x 500 x 600 mm and allows a maximum test specimens load of 100 kg. The Damper Shock can easily be connected to other test chambers and be operated with the familiar S!MPATI control software.

Weisstechnik supplies its Damper Shock either with refrigerant R-23 or the new R-469A, winner of the German Innovation Prize. In the test space, the temperature range is between - 65 °C and + 200 °C.

-

BÜCHI optimizes safety and durability of industrial evaporation with new 50 L Rotavapor® R-250 Pro

With the launch of the Rotavapor® R-250 Pro BÜCHI Labortechnik AG introduces an update of the industrial evaporation unit with the capacity of a 50-liter evaporation flask. The new system offers a unique operating concept, the proverbial high BÜCHI quality, many safety features and a robust design to improve demanding workflows in large-scale rotary evaporation. Conveniently, the interface from the benchtop Rotavapor® R-300 to the industrial 20-liter R-220 Pro and the new R-250 Pro remains the same, so scaling up has never been easier.

Like all BÜCHI rotary evaporators, the newest member of the proven evaporator family features the same level of robustness, Swiss quality and ease of use, delivering superior performance regardless of the scale of evaporation requirements. “The Rotavapor® R-250 Pro is at the forefront of advanced technology with features that increase automation and ease of use to make industrial evaporation safer and more reliable,” said Ralph Unternaehrer, BÜCHI product manager for industrial evaporators.

The newly developed Open Interface and BÜCHI Cloud Services enable remote control and monitoring of the Rotavapor® via a desktop computer, laptop or mobile device. Convenient push notifications with key process parameters, predictive maintenance, effortless firmware updates and data logging options improve the user experience and minimize the risk of errors and downtime. Thanks to BÜCHI sensor technology, consisting of a foam sensor, a level sensor and a cooling temperature sensor, unattended distillations are also possible, contributing to maximum user safety.

In addition to the proven 7-inch (17,78 cm) display, an 8.7-inch (22 cm) capacitive touchscreen provides a comprehensive overview of all process parameters for intuitive operation of the system. The touchscreen allows easy display of all settings and current measured values, including process history graphs. The function is a perfect tool for creating and editing methods and SOPs. The instrument offers maximum safety with safety-coated glass and several built-in safety mechanisms, such as overtemperature and overpressure control. The use of high-quality materials ensures a long service life even under harsh production conditions in 24/7 operation.

-

Evaporation guide: matching your system to your needs

How to find the perfect partner for your evaporation needs.

There are so many different evaporation systems available, it can be difficult to choose the ideal fit for your goals. Our free guide is here to help you find the perfect match for your samples, your applications, and your needs. Discover if an industrial evaporator, laboratory evaporator, parallel evaporator, or glass oven is most suitable for:

Applications such as R&D, production, bars & restaurants, cannabis processing, or testing labs;Various batch sizes and flask sizes;Foamy or sunlight-sensitive samples;Frequent evaporation;Automation or digitalization options.Ensure you are using the most appropriate system for your methods to boost efficiency and safety in your lab.

Download "Evaporation guide" or contact us.

-

Fill it fast. Romaco's answer to COVID-19

High speed liquid filling line for vaccine production shipped in 8 months!

Facts that you need to know:

Output up to 24,000 vials per hour.Shipped in 8 months.oRABS included as standard, more containment solutions available.Shortest time from line delivery to vaccine production thanks to Romaco Validation Package.Robust turnkey solution including vial washer, depryrogenation tunnel, filler and capper for the highest OEE.Several completely customizable cartoners and secondary packing solutions to choose from.Romaco turnkey COVID-19 vaccines production solution, ready in 8 months, includes all that cusotmers need in a high speed aseptic liquid filling line:

In line check weighing system.Batch report creation and exportation via HMI.Fully GMP compliant desing and processes, including GMP management of products flow with pre-loading of rubber stoppers and alu-caps under oRABS.Viable and non-viable environmental controls.GMP management of sampling and rejections.Balcony desing for full process visibility and high ergonomics.Available for though-wall installation.100 % stoppering verification.100 % crimping force verification.Vaccine production line includes:

WM 840 Washing machine.T800/H2C3+ Depyrogenation tunnel.VF 24 Aseptic liquid filler.MAC 4 Capping machine.Fill it fast!

-

New Launch - Perten Glutomatic® 2000 System

New Launch - Perten Glutomatic® 2000 System

From the leaders in gluten analysis, PerkenElmer is excited to release the Perten Glutomatic 2000 System - the most modern, user-friendly, and reproducible gluten analysis system available.

New system. New features. New benefits.

• Touchscreen – The new touchscreen makes the system easy to use. The screen prompts and guides users through the various approved gluten test procedures. This improves repeatability and reduces user influence on the results. The UI can be set to different languages.

• Connectivity in multiple ways – The new GM 2000 allows certain types of balances from OHAUS® and METTLER TOLEDO® to be connected to capture weight measurements at various steps in the method. It also connects the centrifuge to the GM and informs the operator when centrifugation is complete. The GM 2000 provide USB and ethernet connections to PC/LIMS systems. All of this not only speeds up analysis but removes sources of user and transcription error.

• Automated calculation – Whether you connect the GM 2000 to a balance or input weights by hand, the GM 2000 automatically calculates the results, presents them on the touchscreen, and stores them for subsequent viewing and archiving.

• Automated reagent addition – The GM 2000 has the capability to automatically add the 4.8ml NaCl Mix solution at the beginning of the mix step. This frees operators time from manual addition. It also improves method conformance and repeatability removing by reliance on the operator.

• World and industry standards – For over 40 years, the Perten Glutomatic has literally set the standard for gluten testing. Glutomatic and Gluten Index results from the ICC, AACC and ISO method standards are commonly reported in many national and international crop reports. The Perten Glutomatic is the only instrument validated for the Glutomatic/Gluten Index approved methods.

-

Pfeiffer Vacuum presents new turbopumps HiPace 350 and HiPace 450

With the HiPace 350 and 450, Pfeiffer Vacuum presents a turbopump especially dedicated for applications like mass spectrometry, electron-microscopy, metrology tools, particle accelerators and plasma physics. In addition to analytical, vacuum-process and semiconductor technology, their broad range of applications also includes coating, research & development and industrial applications.

HiPace 350 and 450 provide high performance combined with low weight and a small footprint. Based on a hybrid bearing, a combination of ceramic ball bearings on the fore-vacuum side and permanently magnetic radial bearings on the high vacuum side, these HiPace turbopumps have a particularly robust bearing design and guarantee reliability.

The sophisticated rotor design of the turbopumps results in a high pumping speed for light gases. High backing pump compatibility and high gas throughput as well as excellent compression for light gases are made possible by the innovative rotor design. The rotor design provides high cost-efficiency and flexibility, which allows the pumps to be installed in any orientation.

“These turbopumps are the best combination of size and performance. HiPace 350 and 450 stands for compact and powerful turbopumps in the pumping speed range of 300 to 700 l/s and an extraordinary pumping speed for light gases“, says Florian Henss, Head of Product Management Turbopumps.

The integrated HiPace drive electronics offers a variety of communication interfaces, including ProfiNet and EtherCat without any increase in physical size. Remote and sensor functionalities allow the analysis of pump data, such as temperatures. Their quiet operation and improved gas loads are setting new standards in the vacuum industry. The pumps are certified to Semi S2, UL, CSA and Nema 12.

Bearing maintenance on-site is possible. Bearing exchange can be done on customer site. The pumps can run up to 5 years without service.

-

Chromapedia: The complete guide

Essential knowledge for developing and performing the optimal flash chromatography and prep HPLC method.

Rely on concise theory and clear explanations of all parts of the chromatography process. Use chromatography basics to develop your own method with consumables, detection methods, stationary and mobile phases that ideally fit your application.

With Buchi guide, gain valuable information on how to:

Select the most appropriate detection method for your needs.Find, use and care for the ideal column or cartridge.Choose the ideal stationary phase and mobile phase.Establish conditions with TLC and analytical chromatography and upscale to flash or prep HPLC.Use efficiency, retention and selectivity to improve resolution.Avoid endless repeats to establish the perfect conditions by downloading Buchi guide and smartly developing and running your method.

Download "Chromapedia complete guide" or contact us.

-

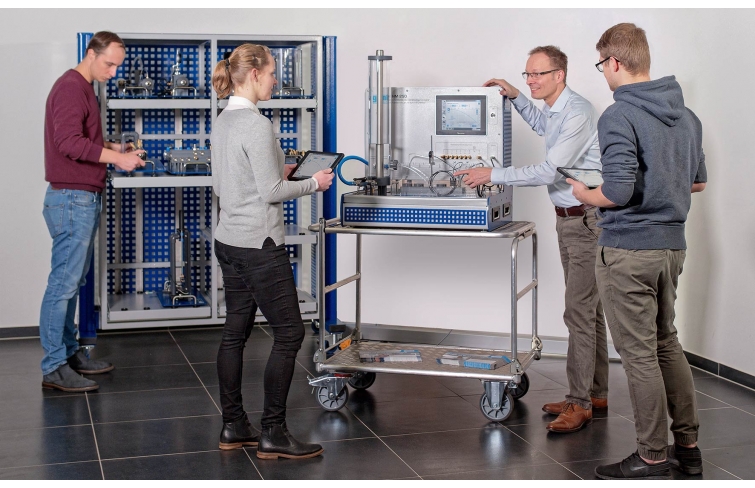

Remote Learning on the fundamentals of fluid mechanics

GUNT are proud to present our revolutionary new Fluid Line for teaching fundamentals of fluid mechanics.

When it comes to fundamentals of fluid mechanics the hydraulic bench has been at the forefront of hands-on teaching for many decades, and in its time, it was an innovation without equal.

GUNT Fluid Line HM 250 includes remote access, USB interface, screen mirroring via WLAN, touch screen control and many more features. Making social distancing, and remote teaching possible.

For instance, the HM 250 uses RFID technology which automatically identifies the respective experiment once it is placed onto the base unit.

The experiments include:

Visualisation of pipe flow.Measurement of flow profile.Visualisation of streamlines.Continuity equation.Measurement of jet forces.Free discharge.Bernoulli's principle.Losses in pipe elements.Fundamentals of pipe friction.Pressure curve along the inlet section.Open channel.Even if you are not interested into our new Fluid Line you can use our free e-learning course ”Fundamentals of fluid mechanics” for you and your students.

-

PURE vacuum. Nothing else.

An innovation in vacuum technology. Clean and oil-free 10-3 mbar vacuum.

Vacuubrand team of experts developed VACUU·PURE® for contamination-free vacuum that lets your clean processes run efficiently. Vacuubrand dry screw pumps meet challenges where other technologies fall short.

The working principle of VACUU·PURE® is based on gap sealing. The unique operating principle enables contact-free rotation of the spindles. The vacuum pump operates oil and abrasion free. This ensures an ultrapure vacuum as well as contamination-free exhaust air. In addition, there is no wear due to abrasion and no need for oil changes, allowing for continuous operation.

The chemically resistant version VACUU·PURE® 10C, features wetted materials made of chemically resistant polymers. A thick-walled PEEK encapsulation protects the spindles and stator in the pumping chamber, providing high chemical resistance. The use of a cold trap is unnecessary in many cases – another plus for reliable, continuous and economical operation.

Applications:

Fore vacuum generation for turbomolecular pumps.Analytical applications.Regeneration of cryo pumps.Vacuum drying.Freeze drying.Heat treatment.Degassing.Coating.Distillation.Schenk line.VACUU·PURE® 10C: Screw pump for aggressive gases and vapors

10-3 mbar vacuum range.Pumping speed 9 m3/h.100% oil-free.Chemically resistant.No wear parts.VACUU·PURE® 10: Screw pump for non-corrosive applications

10-3 mbar vacuum range.Pumping speed 10 m3/h.100% oil-free.No abrasion.No wear parts.Some customer experiences with VACUU·PURE®.

"With VACUU·PURE®, we finally get a hydrocarbon- and abrasion-free vacuum in a vacuum range of down to 10-3 mbar."

"We were particularly impressed by the fact that VACUU·PURE® has good flow rates even at higher pressures. For this reason, we can use VACUU·PURE® as early as the initial evacuation of our UHV systems (ultrahigh vacuum systems). We avoid switching between different pump technologies for pumping out our systems and use as a backing pump."

"In all tests, VACUU·PURE® demonstrated very good performance, even in the case of an unusually high vapor load. The regeneration mode of VACUU·PURE® is very helpful to be able to start the next process very quickly. We believe that there is no comparable vacuum pump."

-

Chromapedia volume 4: Method development in flash chromatography and prep HPLC

Careful analysis of sample solubility and separation behavior prior to purification enables users to achieve reproducible results in an efficient way. Once the ideal conditions are found, upscaling to flash chromatography, prep HPLC or a combination of both can be easily achieved.

Use BUCHI guide to learn all steps of method development, including:

Definition of purification method (flash or prep HPLC).Analysis of sample solubility.Screening of suitable conditions for separation by selecting most appropriate mobile & stationary phase.Upscaling to flash or prep HPLC.Improving resolution.Use BUCHI free guide to see how to save time and resources by establishing the optimal method for your own samples.

Download "Chromapedia volume 4" or contact us.

-

SyncorePlus adds a plus to your laboratory

The added benefits of Büchi parallel evaporation systems offer a new level of ease and quality to your process. SyncorePlus Analyst and SyncorePlus Polyvap combine cutting-edge improvements of system features and parts to offer:

PLUS process and analytical safety – Higher precision, accuracy and reproducibility thanks to fully automated system.PLUS analyte recovery – Higher analyte recovery thanks to Flushback Module and cooled appendix.PLUS time and cost savings – Full method performance without any supervision and no need for unnecessary repetitions.PLUS sample safety – No cross contamination due to heated vacuum cover.PLUS compatibility – Supports existing racks and allows for easy and safe sample transfer between other BUCHI instruments.Reap the rewards of full automation and smart system design for easy, dependable and cost-efficient parallel evaporation.

-

Goodbye & hello – The new Asphalt Analyzer YOU

Safe, health and environmentally friendly extractions have always been infraTest goal. Asphalt analyzer producer infraTest is closing the last gap in the open handling of solvents now and are giving insights into recovery for the first time.

infraTest says goodbye to the previous Asphalt Analyzer generation and welcome our new Analyzer YOU series!