NIR-Online X-Sential™

Contact person

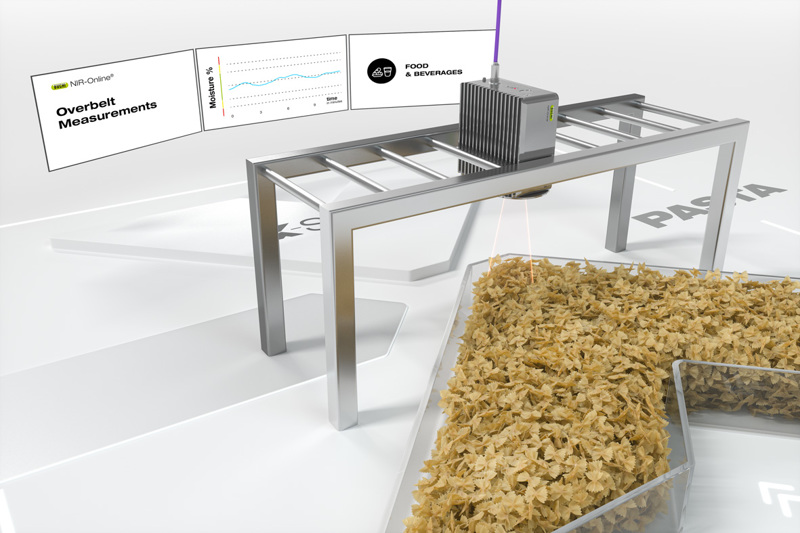

All that is essential for process control.

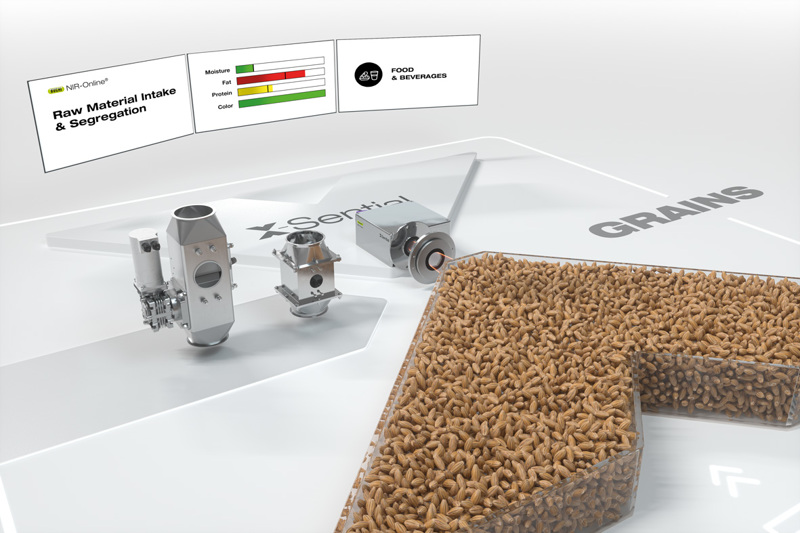

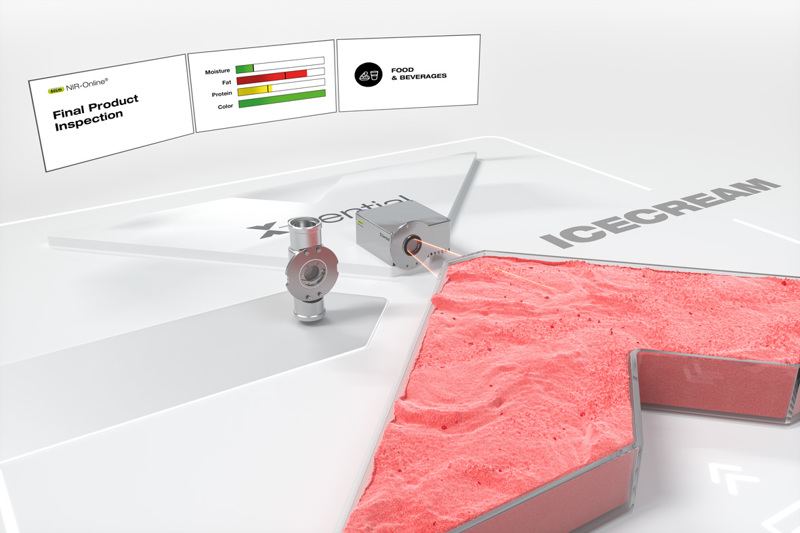

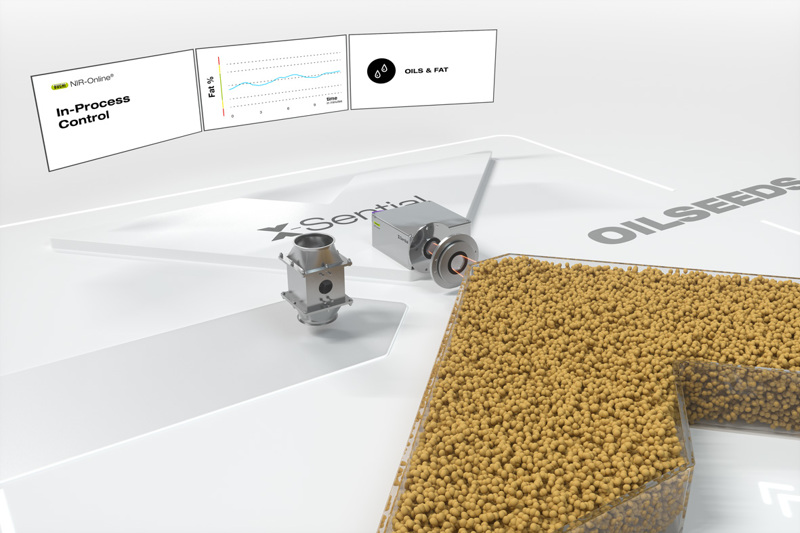

Closely monitoring basic parameters such as moisture, fat, or protein is crucial to correct deviations in manufacturing processes. The X-Sential™ has been developed and designed to be a high-value, cost-efficient, and fit-for-purpose process sensor.

Ease of use

- With its unique AutoCal functionality, there is no need for expert knowledge to operate the X-Sential™. The process sensor can be easily implemented into your existing quality control routines. A wide range of process adapters allows for easy integration into production lines. NIR-Online offers the user optional HMI solutions.

Cost efficiency

- The functional design of the NIR-Online X-Sential™ is fit-for-purpose and, therefore, very cost-effective. The average payback time is less than one year. There is no need for commercial calibration databases or extensive in-house calibration development. It is possible to determine basic quality parameters of raw materials and finished products in large quantities; this minimizes out-of-spec production and the need to rework and allows for correcting your processes in real-time.

Extensive process expertise

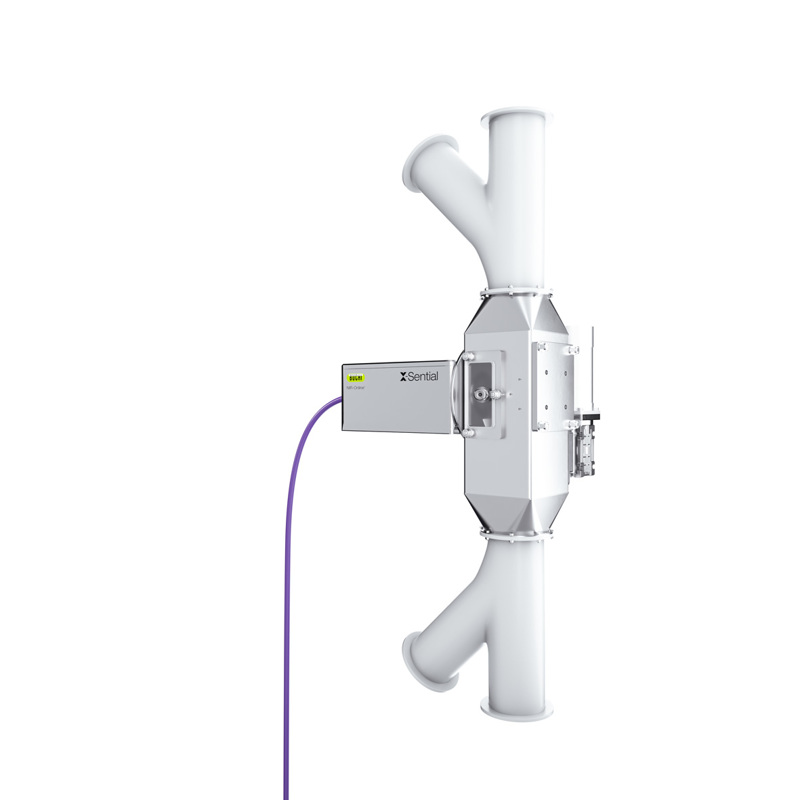

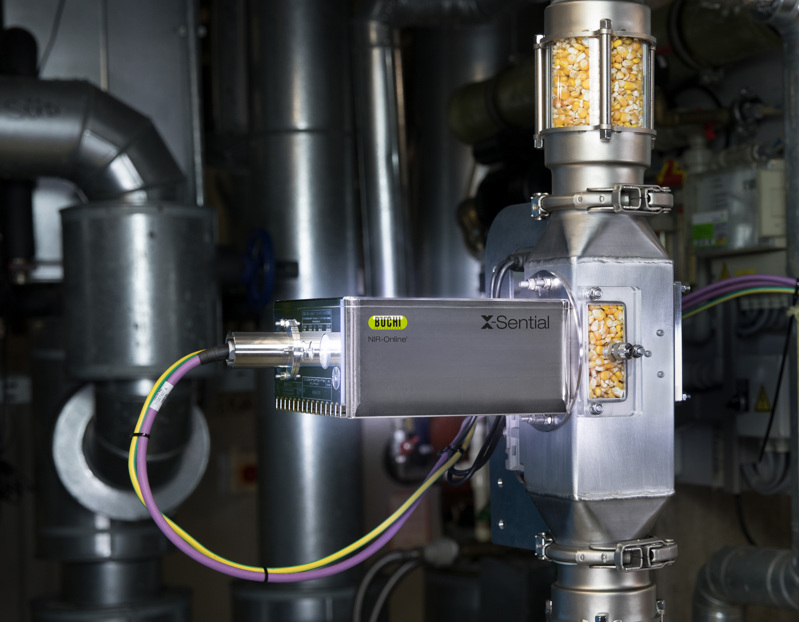

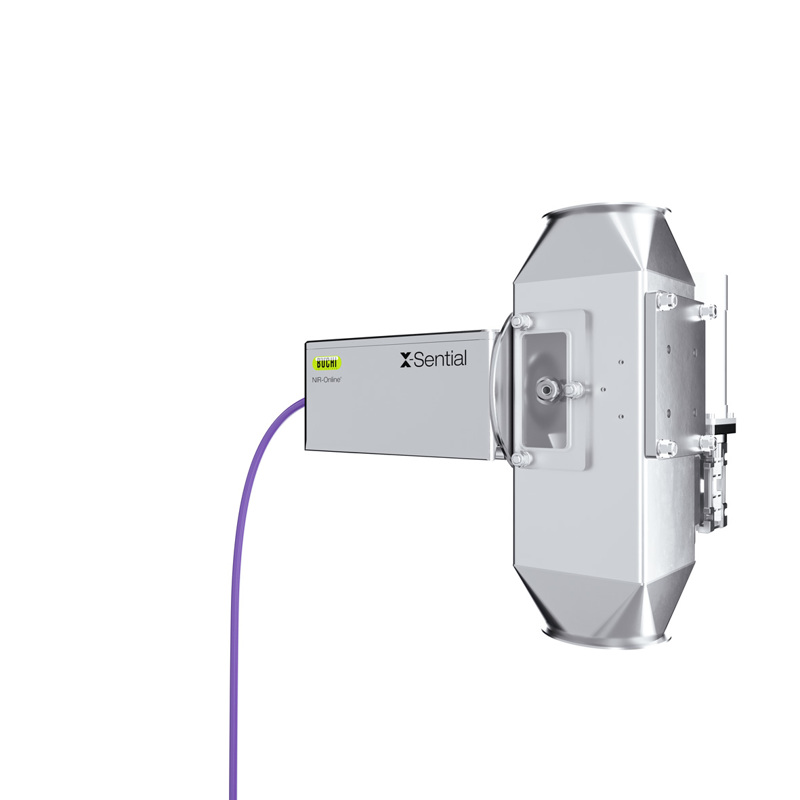

- The NIR-Online X-Sential™ has a dust and water jet-protected sensor enclosure (IP69/X9K). A wide range of ambient and product temperatures is possible using temperature-stabilized spectro-meters. The sensor is a turnkey solution for fast, fluctuating, or discontinuous product flows. The integration into process control systems is straightforward.

Diode array technology

- Sensor spectrometers without moving parts are very fast and robust by design. They are perfectly suited for rough industrial conditions such as vibrations, extreme temperatures, or humidity. This technology allows detection of fast-moving products, e.g., in pipes or on conveyor belts.

Dual lamp

- Maximum system availability through automatic switching to a redundant light source.

Hardware process integration

- BUCHI extensive portfolio of proven process adapters covers, e.g., solid, liquid, pasty, viscous, or corrosive samples at a broad range of pressure and temperature conditions.

Software process integration

- Numerous interfaces for the convenient transfer of acquired data to process control systems, including TCP/IP, OPC DA, Modbus TCP, Profibus, and analog output. Benefit as well from optional device-independent HMI solutions.

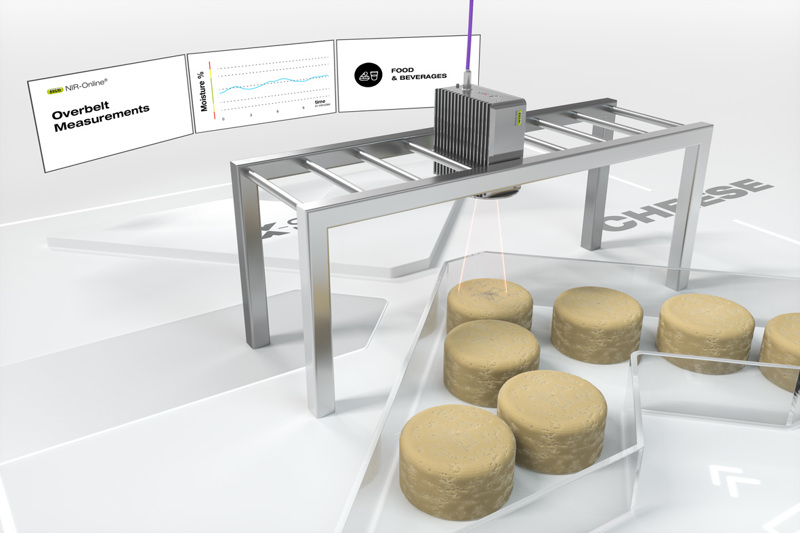

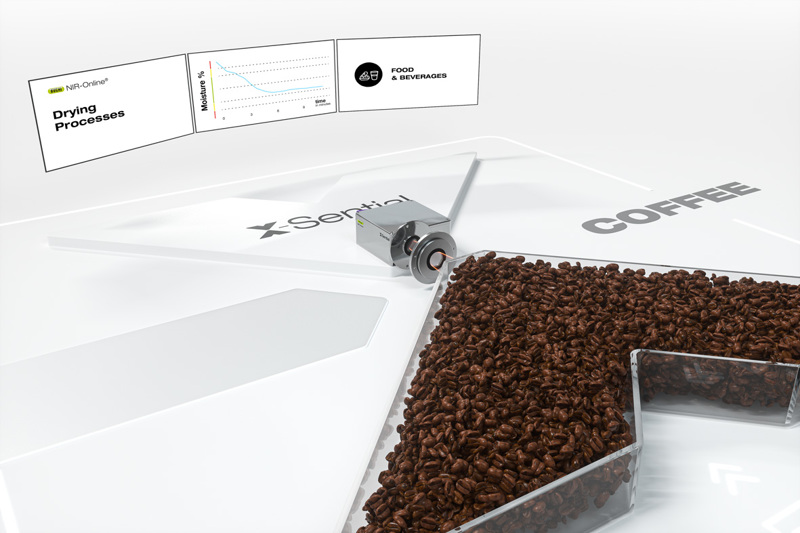

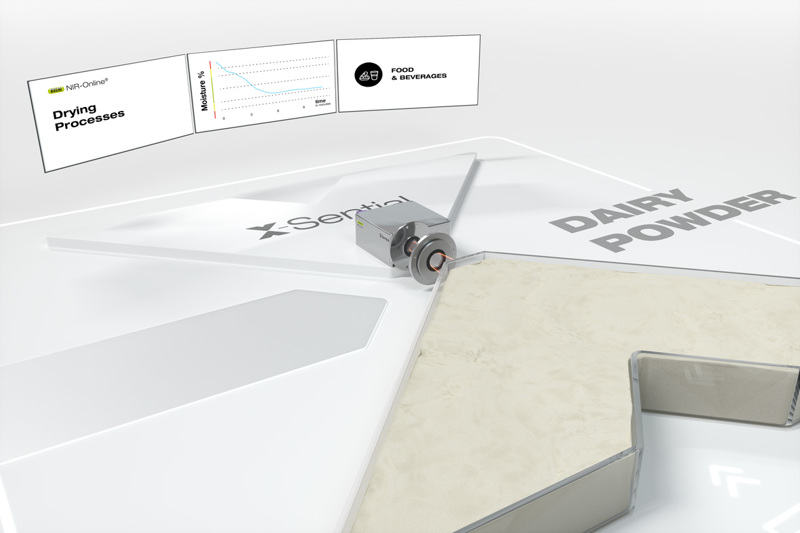

Application examples

NIR-Online Food

Benefit from our experience in industries such as:

- Bakery

- Dairy

- Flour

- Oil seeds

- Edible oil

- Meat

- Sugar

- Sweets

- Tobacco

NIR-Online Feed

Maximize gross profit margins in production and blending of animal feeds, such as:

- Cattle

- Fish

- Mixed

- Pet food

- Pig

- Poultry

- Press cakes

- Silage