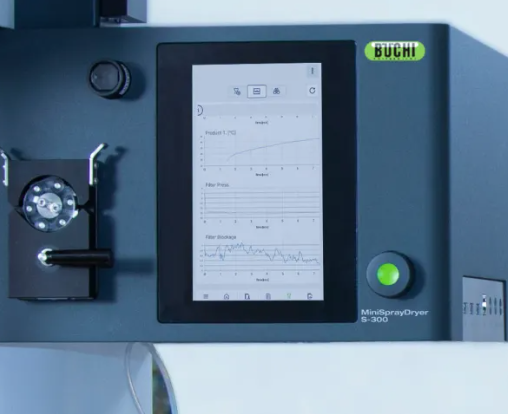

Mini Spray Dryer S-300

The next generation laboratory spray dryer!

The Mini Spray Dryer S-300 offers you unique features you cannot find in any other spray drying equipment.

Highest level of automation and flexibility

With the Mini Spray Dryer S-300 you can benefit from the highest possible automation levels to improve your process efficiency and free more time for your formulations.

- Safe handling of organic solvents.

- Substantial time savings with Auto Mode.

- Higher process regulation and reproducibility.

- Maximal flexibility with remote control possibilities.

- User-friendly operation with method programming.

Improved spray drying performance

The Mini Spray Dryer S-300 allows you to achieve highly reproducible results, speed up the optimization of your formulation and simplify upscaling applications.

- Comprehensive reporting with a push of a button.

- Improved sample protection.

- Improved reproducibility through system design.

- Full compatibility with previous spray dryers.

Clever features that make all the difference

BUCHI focuses on perfecting every detail so you can easily handle the Mini Spray Dryer S-300 and improve your spray drying performance.

- Easy maintenance with new cyclone mounting.

- Coated cyclone for increased yields.

- More stability with ruby stone in the nozzle.

- Higher flexibility thanks to second sample pump.

- Vast expertise in Application Database.

Spray Drying organic solvents

- In combination with the Inert Loop S-395, the Mini Spray Dryer S-300 allows for the safe handling of samples with organic solvents. The nitrogen drying gas is circulated and the solvent is collected as condensate. For your safety, the oxygen level and gas flow in the system are continuously monitored.

Auto Mode

- The Auto Mode allows you to program your Mini Spray Dryer S-300 Advanced and run your method automatically. The instrument will heat up, condition the outlet temperature, spray pure solvent, spray your sample, spray pure solvent again and shut down after the sample is processed. The auto mode improves the time efficiency of your process, especially during repetitive tasks.

SI Values

- All parameters in the Mini Spray Dryer S-300, such as spraying gas, drying gas and pump speed, are provided in SI values and are automatically regulated by the system. These features maximize the reproducibility of your process.

Remote control

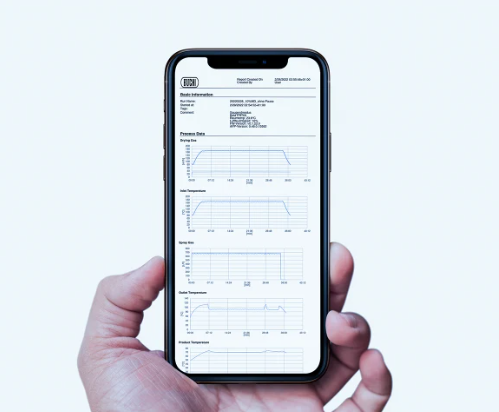

- Control or monitor the Mini Spray Dryer S-300 from anywhere at any time. The app on any mobile device or computer grants you full access to the entire user interphase of the system. With remote control options, you gain flexible time management and fast reaction times to process alterations.

Method programming

- Save time and hassle by saving your runs as methods and repeating them later. You can also program a sample queue to run one sample after another on your Mini Spray Dryer S-300 for added convenience.

Reporting

- All the runs you perform on the Mini Spray Dryer S-300 are recorded and saved on the instrument. With the push of a button, you can easily generate a PDF report or a .csv file with your process data.

Sample protection

- To give you more information about the thermal influences on your sample, the Mini Spray Dryer S-300 allows you to monitor both the outlet temperature and the final product temperature. This information can help you better protect your samples, especially when spray drying heat sensitive samples.

Coated cyclone

- Reduce sample loss during lab spray drying thanks toa cyclone with a conductive coating that reduces the ability of your sample to stick to the walls.

Application

- With more than 40 years of experience in laboratory scale spray drying, BUCHI has accumulated vast application know-how. Find one of the thousands of publications with BUCHI spray dryers in scientific libraries or explore our online Spray Drying application database to find applications that match your needs.

With the Mini Spray Dryer S-300, you can reproduce the results that you achieved with older models of the BUCHI Mini Spray Dryer. You will not lose any of you valuable work for a quick, seamless transfer to the new instrument.

| Characteristics / Model | Mini Spray Dryer S-300 220 °C | Mini Spray Dryer S-300 Advanced 220 °C | Mini Spray Dryer S-300 Advanced 220 °C Pro | Mini Spray Dryer S-300 Corrosives 220 °C | Mini Spray Dryer S-300 Corrosives 220 °C Pro | Mini Spray Dryer S-300 Advanced 250 °C | Mini Spray Dryer S-300 Advanced 250 °C Pro | Mini Spray Dryer S-300 Corrosives 250 °C | Mini Spray Dryer S-300 Corrosives 250 °C Pro |

| Sample composition | water | water, organic solvents | water, organic solvents | acids, alkalines, water, organic solvents | acids, alkalines, water, organic solvents | water, organic solvents | water, organic solvents | acids, alkalines, water, organic solvents | acids, alkalines, water, organic solvents |

| Maximum inlet temperature | 220 °C | 220 °C | 220 °C | 220 °C | 220 °C | 250 °C | 250 °C | 250 °C | 250 °C |

| Auto mode and Method mode | No | No | Yes | No | Yes | No | Yes | No | Yes |

| Yield up to % | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Minimum partical size | 1 μm | 1 μm | 1 μm | 1 μm | 1 μm | 1 μm | 1 μm | 1 μm | 1 μm |

| Maximum partical size | 25 μm | 25 μm | 25 μm | 25 μm | 25 μm | 25 μm | 25 μm | 25 μm | 25 μm |

| Maximum sample throughput (H2O) | 1 l/h | 1 l/h | 1 l/h | 1 l/h | 1 l/h | 1 l/h | 1 l/h | 1 l/h | 1 l/h |

| Nozzle type | two fluid nozzle, three fluid nozzle, ultrasonic nozzle | two fluid nozzle, three fluid nozzle, ultrasonic nozzle | two fluid nozzle, three fluid nozzle, ultrasonic nozzle | two fluid nozzle, three fluid nozzle | two fluid nozzle, three fluid nozzle | two fluid nozzle, three fluid nozzle, ultrasonic nozzle | two fluid nozzle, three fluid nozzle, ultrasonic nozzle | two fluid nozzle, three fluid nozzle | two fluid nozzle, three fluid nozzle |

Spry Drying Applications

Pharma: Laboratory-scale spray drying is a vital process in the pharmaceutical industry, used for the formulation and development of various drugs and medications.

Chemicals / Materials: Laboratory-scale spray drying is a versatile and efficient method for producing a wide range of materials in the chemicals and materials science field.

Batteries: Laboratory-scale spray drying is a valuable technique in battery research for the fabrication of electrode materials.

Food: Encapsulation of additives, controlled release, nutraceuticals, functional foods, flavors, vitamins, proteins, probiotic bacteria, juice concentrate, milk powder.

Biotechnology: Cells, bacteria and protein encapsulation, cell transplantation, biotransformation.

Cosmetics: Drying, encapsulation of liquids, encapsulation of solids, micronization.