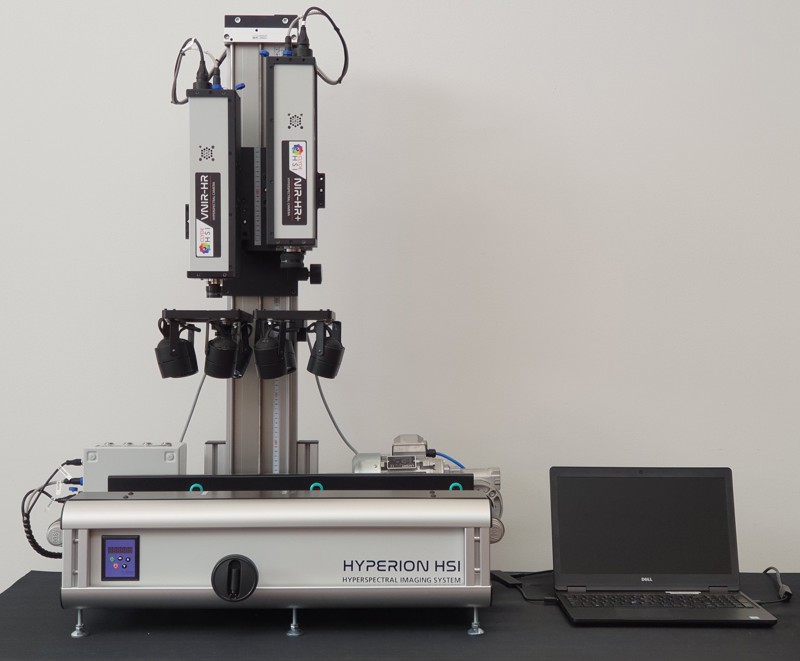

SC-C80 Conveyor scanning system

Benchtop Conveyor System with 220mm wide conveyor belt. Adaptable to a wide range of processes.

Each ClydeHSI conveyor scanner comprises of a complete turnkey hyperspectral solution that includes: spectral camera, scanning stage, interchangeable sample trays, lighting system, focus target, reflectance standard, data acquisition, viewing and analysis software.

ClydeHSI conveyor systems are quick and easy to set up on standard tables, and can acquire high resolution spectral images in seconds. All scanners can hold up to two spectral cameras at a time with multiple configurations available. Additionally to this system have efficient height adjustment and fully integrated lighting stage.

The ClydeHSI SC-C80 is capable of single and dual camera operation with simultaneous data acquisition, and is fully compatible with all ClydeHSI hyperspectral cameras, light sources, and our unique hyperspectral data acquisition and analysis software. This ensures broad adaptability to applications and the capability to capture hyperspectral data from a broad spectral range.

| Spectral range | 400 - 2500 nm |

| Scanning area | 250 mm |

| Scan speed | 0.2 to 750 mm/s |

| Scanner track range | Determined by sample length |

| Feed in/out | Gravity roller system |

| Sensors | Speed adjustment for square pixels |

| Camera stand-off distance | Up to 700 mm |

| Dimensions | 800 x 300 x 1000 mm |

| Weight | 90 kg |

System entry level configuration comprising of the following:

- SC-C80 Conveyor Belt Scanner

- VNIR-HR 400 to 1000nm, hyperspectral camera

- NIR-HR+ 950 to 1700nm hyperspectral camera

- Broad-band illumination

- Fore Objective Lens Kit

- Setup, focus, and calibration tiles

- Workstation computer

- Acquisition, visualisation, and analysis software

- Installation and application support