Viscometry

The product range initially includes a variety of different and high quality DURAN® glass capillary viscometers that comply with the relevant DIN, ISO and ASTM standards. After production, our viscometers are calibrated by direct comparison with reference viscometers of the Physikalisch-Technische Bundesanstalt. Automated measurement devices range from automatic timekeeping (ViscoClock plus), to automated pumping / pumping in the viscometer (AVS®), working with a waste system and PC control (AVS® 370) to fully automatic AVS®Pro III sample changer. Accessories, e.g. for sample preparation, completes the program.

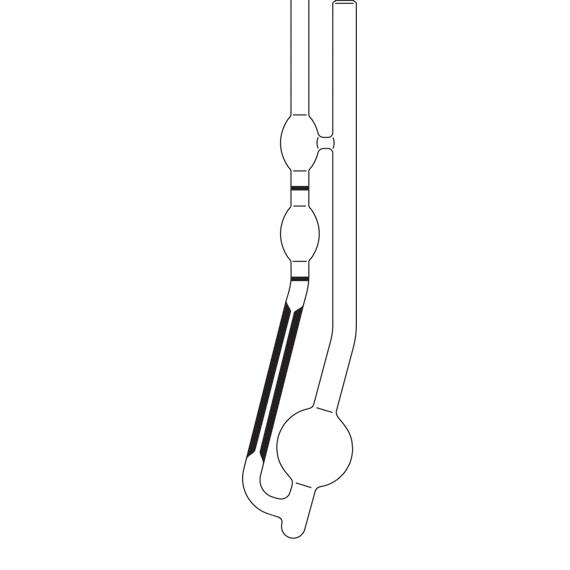

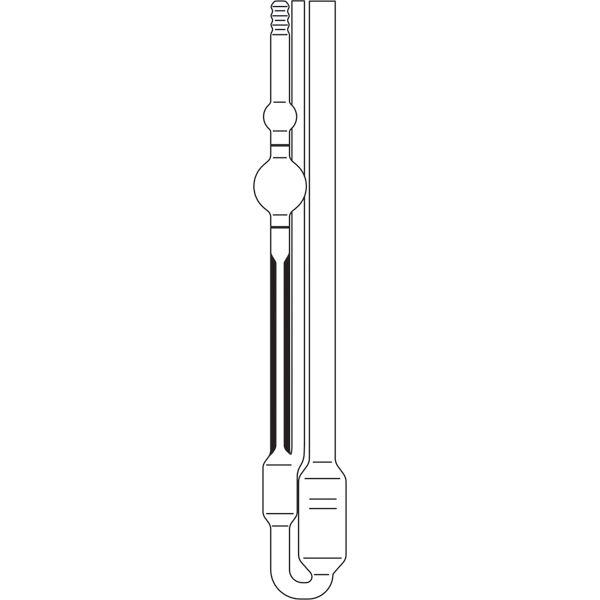

Ubbelohde Viscometers with venting tube.

Glass capillary viscometers.

Viscometers without venting tube.

Glass capillary viscometers.

ViscoClock plus

- Electronic timing unit for glass capillary viscometers, including hand pump VZ 6550.

- The ViscoClock plus is an electronic timing unit for glass capillary viscometers used to determine kinematic and relative viscosity.

- The ViscoClock plus is especially designed for Ubbelohde type viscometers which are well-known for highest precision.

- The ViscoClock plus automatically measures the flow time of temperature-stabilized liquids in capillary viscometers by means of infrared light barriers: the manual measurement with a stopwatch becomes obsolete.

- The large display enables easy read-off of flow times and additional information: date, time, sample ID and viscometer ID.

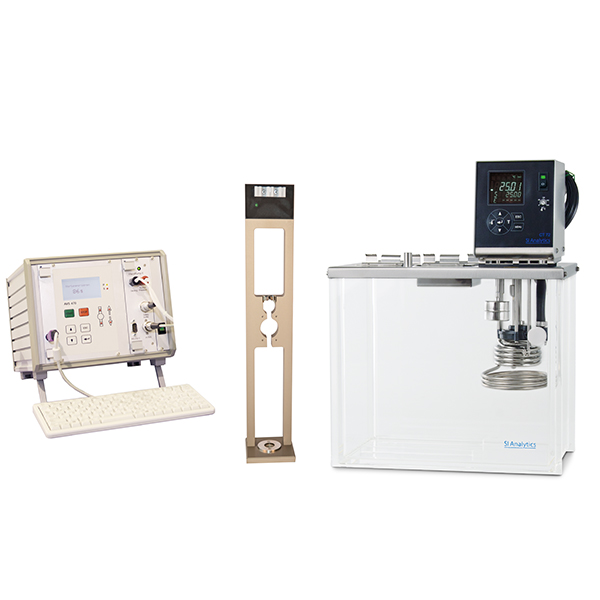

AVS® 470 (TC) viscosity measuring system

- The AVS® 470 is a viscosity measuring device for capillary viscometers which does not require an additional PC.

- The AVS®470 (TC) is equipped with a ViscoPump III, VZ 8562 for detection of liquid meniscus by thermoelectric sensors. For connecting, suitable TC viscometer of SI Analytics® are required. TC viscometers are especially used for opaque (non-transparent) samples. In case of transparent samples, there is the alternative AVS® 470 (opt). In this device, the liquid detection is carried out by means of IR light barriers.

- According to the application, the AVS ®470 can pump the sample liquid by “suction” or “pressure” mode into the measuring bulb of the viscometer.

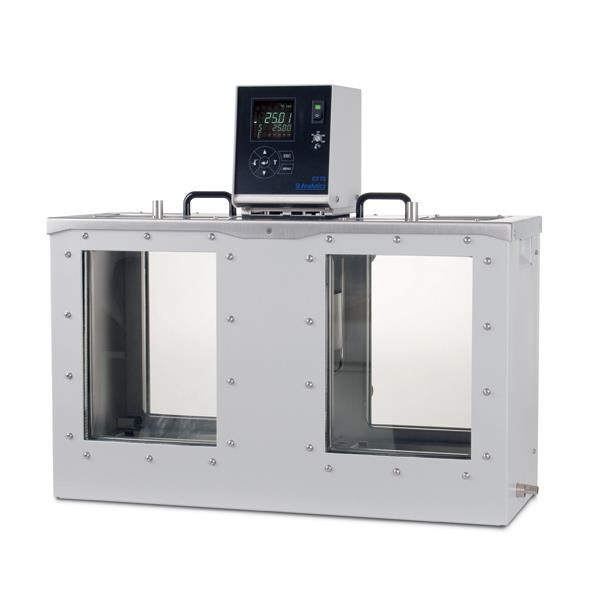

Transparent thermostat CT 72

- For viscosity measurement using glass capillary viscometers.

- Working temperature +5 °C to +150 °C, stainless steel container with thermal insulation.

- 2 or 4 measuring positions.

- Suitable for manual measurement or AVS®/S measuring stands.

- Heater with Pt 100-PID control.

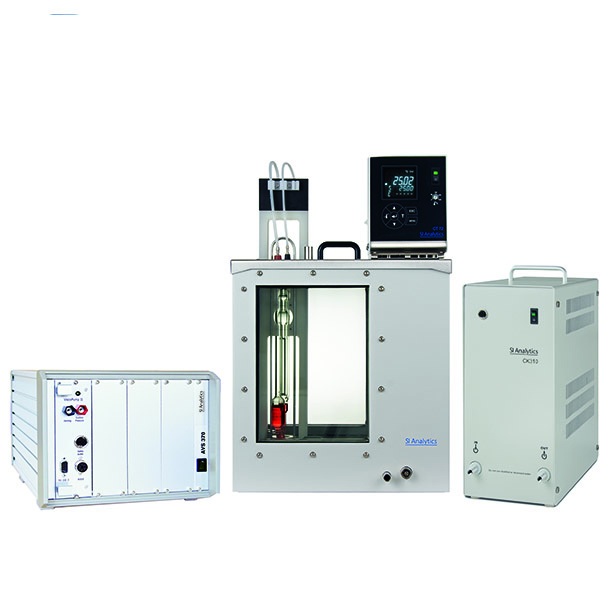

AVS®370 viscosity measuring system

- The AVS® 370 is a PC controlled viscosity measuring device for capillary viscometers.

- System includes software WinVisco, one ViscoPump III for one measuring position, a measuring stand AVS®/SK, a thermostat bath CT 72/2, and a cooler CK 310.

- The AVS® 370 can be upgraded with maximum 8 ViscoPumps for parallel use of multiple measuring positions.

- According to the application, the AVS ®370 can pump the sample liquid by “suction” or “pressure” mode into the measuring bulb of the viscometer.

- Optionally, the AVS®370 can be equipped with a waste and rinsing system.

AVS®Pro III, autosampling system

- Automatic sampler for viscosity measurement using capillary viscometers.

- The AVS® Pro III automatic sampler is a PC-controlled, fully automated instrument for the determination of the viscosity, viscosity number, intrinsic viscosity etc..

- In spite of the high sample throughput, AVS® Pro III provides maximum accuracy and reproducibility. Furthermore, working with the automatic sampler is easy and allows unattended 24 hour operation.

- The AVS® Pro III, meanwhile in its 3rd generation with many improvements, has proved itself especially for quality control of polymers. Worldwide, most producers of polyamide, polyesters and other polymers trust in the AVS® Pro III. And increasingly, also many polymer processing companies are using the AVS® Pro III in their QC.

- Depending on application and customer’s demands, the instrument can be delivered in various configurations - in general 2 to 4 measuring positions; macro or micro dosing modul, depending on viscometer types; two rinsing options: using next sample or rinsing agent with subsequent drying; variable waste system.

- The configuration is adjusted together with the customer.