Cartoning and end-of-line solutions

With numerous innovations and advanced technologies, Romaco Promatic is a globally recognised brand. Customers in the pharmaceutical, cosmetics and chemical industries trust in the groundbreaking cartoning solutions, rich know-how and excellent customer service of Romaco Promatic.

High speed and quality packaging with various carton closing options.

Customised transport systems for special configurations and specific products shape.

Romaco solutions:

- Horizontal cartoning machines.

- Vertical cartoning machines.

- Track & Trace / case packer.

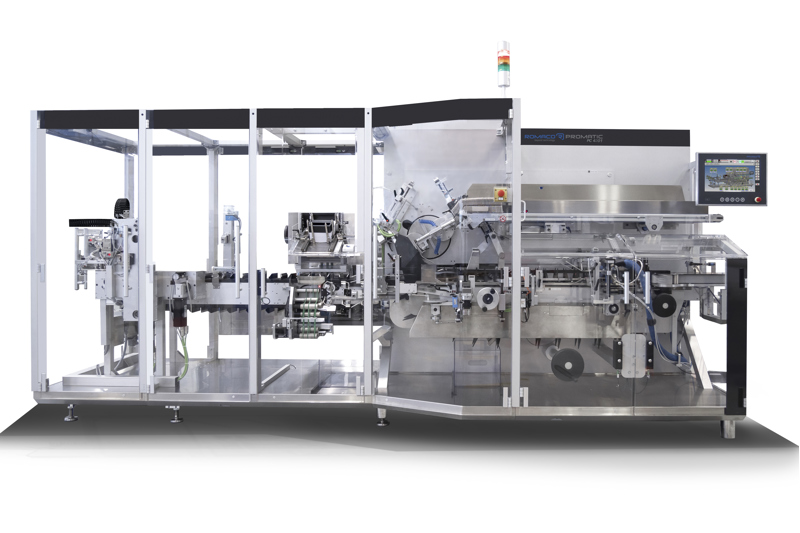

P 91 series cartoners

Horizontal intermittent motion cartoners. P 91 cartoners can be equipped with modular, multiple feeding systems to pack pharmaceutical, nutraceutical or chemical products. P 91 is designed for silent operations, no vibrations and ergonomic loading of packaging components.

Highly tolerant regarding carton quality, including recycled paper cartons. Seamless integration of all kinds of feeding system for pharmaceutical, nutraceutical, chemical products. Systems have zero waste logic – carton and leaflet/booklet are fed only when product is present.

- Maximum 90 cartons / minute.

- Smart change-over kit (guided format change-over via HMI and wireless digital position indicators.

- Counter pusher for unstable products.

- Carton closing via tuck-in or glue.

- Fully customised based on product handling.

- Can integrate any vision system.

- Patented carton pick-up and positive forced opening system.

- Ergonomic working height for maximum operating convenience.

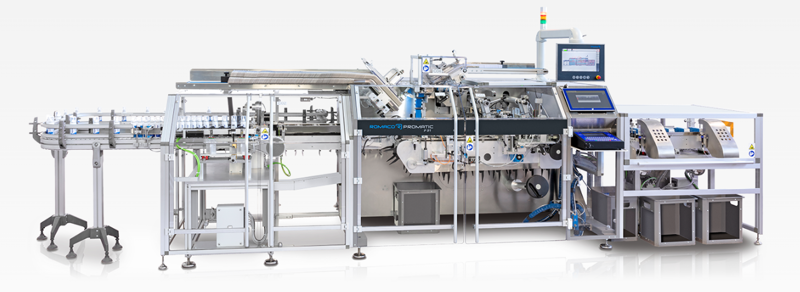

PC 4000 Series cartoners

Horizontal continuous motion cartoners. The PC 4000 cartoners consistently deliver versatility via a wide range of tailor-made feeding options for different products, together with ergonomics and efficiency.

Seamless integration of all kinds of feeding system for pharmaceutical, nutraceutical, chemical products. Ergonomic working height for maximum operating convenience. Systems have zero waste logic.

- Maximum 400 cartons / minute.

- Smart Change-over kit (guided format change-over via HMI and wireless digital position indicators).

- High speed and gentle handling of all products, including fragile glass ampoules.

- Balcony design.

- Verification of product presence in bucket.

- Can integrate any vision system.

- Fully customised based on product handling.

- Patented carton picking up and opening the cartons.

- Low vibrations and noise levels thanks to servo motors and belt drives.

- Lowest Total Cost of Ownership in the industry.

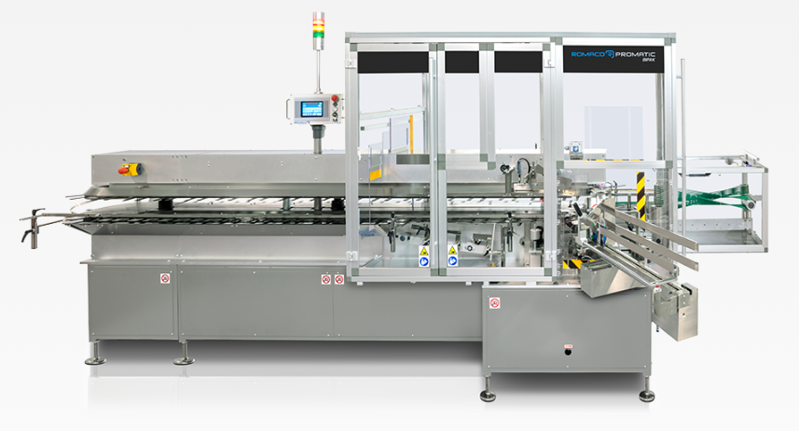

BIPAK Series vertical cartoners

Reliable, versatile and tireless: Bipak cartoners can be operated in intermittent or continuous motion and are able to handle different types of carton closures. A wide range of automatic feeding units is available to completely automatise the packaging machine.

Cartoning machine with wide range of accepted formats. Manual and automatic feeding of components can coexist on the same machine. Complete set of size parts for the entire working range of formats supplied with the machine.

- Up to 100 cartons / minute.

- Rejection of faulty products in lockable boxes with load control.

- Various product feeding asystems such as pick and place, anthropomorphic robots and more can be installed on the machines.

- Can be equipped with ancillary feeding system such as booklet feeders, pre-folded leaflet feeders and more.

- Any vision system of choise can be integrated.

- Exceptionally silent operations.

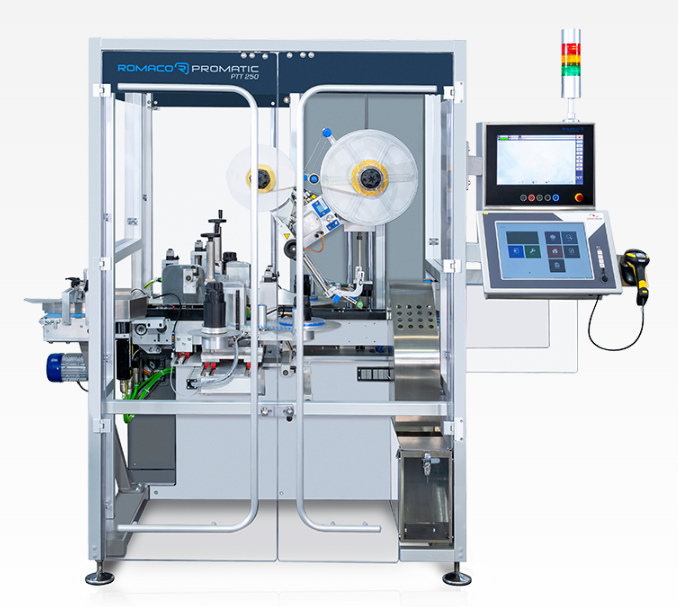

PTT Series for track & trace

Romaco platform for track & trace solutions. PTT machines can integrate various carton coding systems as well as labelling systems for tamper evidence on carton flaps and for vignette on top of the cartons. All operations are controlled by the vision system you select. PTT machines can be installed downstream of any cartoner or checkweigher.

Flexibility to install any kind of vision system and integrate serialization software or to use a Romaco Vision System partner for a turnkey solution. Suitable to integrate your printer of choice for carton coding.

- Up to 400 cartons / minute.

- Compact footprint, suitable for integration into existing production lines.

- All operations can be performed from operator’s side.

- Rejections sorted in lockable bins.

- Vignette labelling and reading.

- Variable data printing and verification.

- Tamper evident labellers.

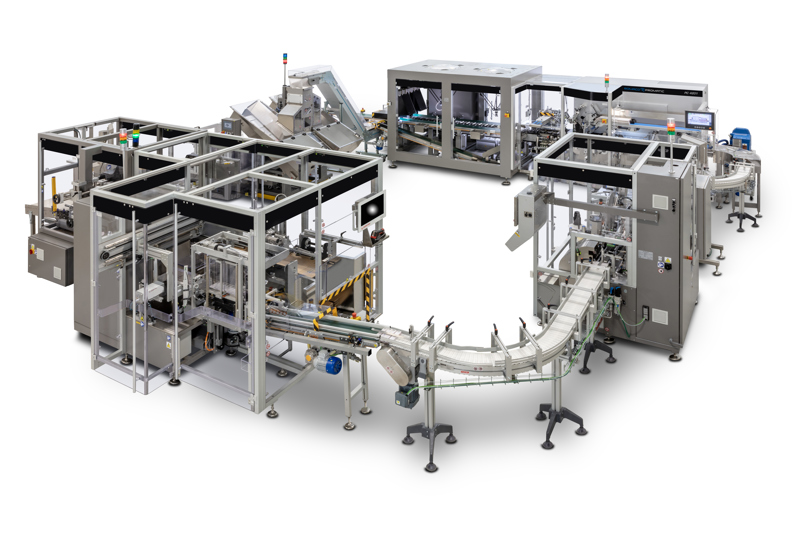

PAK Series for case packing

Case packing and aggregation. Semi-automatic or fully automatic case packer with ergonomic features and options for labelling and aggregation to comply with pharmaceutical industry requirements.

Minimal need of operator intervention for loading components during the run due to high-capacity case magazine that enables automatic lifting of the cases to working height. Forced uprighting of the cases via a double arm fitted with suction cups and Venturi vacuum unit.

- Dedicated roller conveyors for good products and rejection with case overturning.

- High capacity case magazine.

- Case carry modules for case labelling / aggregation.

- Camera for aggregation.

- Full visibility of product flow and immediate safe access to all functions and operations.